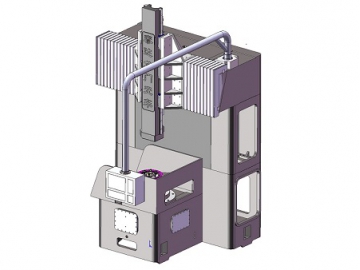

Wheel Disk Vertical Turning Lathe , Gantry Type

Gantry type vertical turning lathes are specially designed for machining inner and outer planes for wheel rims and discs. Due to the excellent overall structural rigidity, the frame’s interior features a wide motion range. The vertical turning lathe is also used to handle other parts similar in shape and size by slightly modifying the positioning clamping mechanism, giving the turning lathe a wide application range.

The two-way feeding action is controlled via a servo motor and driven using a precision ball screw. The servo motor itself is PLC controlled to ensure positioning is accurate and reliable, while knife rest movement is controlled by a strengthened ball screw and linear guideway that perfectly match with no gaps. This prevents vibration deformation during the cutting process and ensures processed work piece flatness.

This turning lathe features a gantry type frame structure. The work piece is loaded from the front of the gantry along the roller guide shaft into the chuck at the top of spindle. Users can refer to the following drawing to configure the operating position layout and assembly line layout.

| Main motor | 11kw/730r/min |

| Main shaft speed | 250r/min |

| Processable diameter of ex-circle | Ф160-Ф600m |

| Longitudinal feed motor | Servo motor |

| Horizontal feed motor | Servo motor |

| Knife rest vertical travel | 420mm |

| Knife rest cross travel | 530mm |

| Machine size | 2750*1400*3240(L*W*H) |

| Total weight | 7.5T |