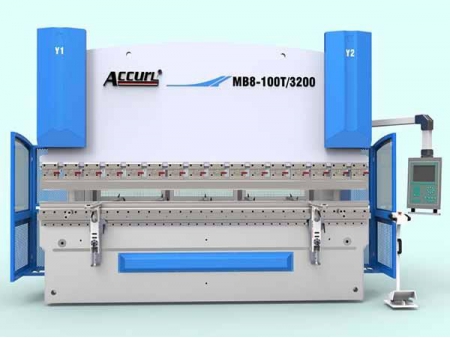

ACCURL-Bend - 3 Axes CNC Press Brake

Request a Quote

Stronger, faster and Deeper Bends

- ACCURL-Bend Series 3 axes CNC press machines redesigned based on users preferences to become a unique machine with its individual electronic and mechanical features.

- Power-Bend Pro Series are among the highest rated machines which will help you increase your productivity and keep costs at minimum level with its user friendly CNC controller and low cost hydraulic maintenance.

- New ACCURL-Bend Pro is exactly what you need for your production where complicated, sensitive, single or multiple bends on high speed are paramount.

Combination of speed and Power

- High quality and repetitive bending is obtained by using synchronized cylinders and valves.

- Automatic utilisation of all axes on startup.

- All ACCURL metal bending machines are designed using SOLID WORKS 3D programming and made with enhanced ST44-1 quality steel using the latest technology

- Rigid upper beam runs on 8-point bearings with bending precision of 0,01 mm.

- Well-known top and bottom tool brands are long lasting hardened and provide precise bending.

- Silent high pressure pump.

High Free Fall Speed

High Bending Speed

High Returning Speed

Features

- Chrome coated cylinders are machined with 0,001 mm precision and pistons are specially hardened.

- Original clamps are user friendly and machined with high precision.

- Front support arms are slideable along machine length and easy to adjust.

- Compact and well-known brand Bosch-Rexroth hydraulics are produced according to CE standards.

- CNC press brake adopt wwo photocells on sides for rear guard.

- Fast tool tightening.

- Optic linear scales are sensitive up to ± 0,01 mm.

- Synchronized working cylinders will give you the best bending result with its perfect repeatability ratio.

- 2 axis ultra strong backgauge system (X=800 mm and R), with ± 0,01 mm. repeatability, moves along rails and ball screw, bending length controlled by CNC controller, foldable back gauge fingers for reverse bending applications.

- Multifunctional and highly programmable, DELEM DA52S CNC controller.

- The metalworking machinery uses SIEMENS electrical system.

- Automatic axis referencing when machine is turned on.

- Side guard is standard meeting CE regulations.

Your best bending solution

- This CNC hydraulic press brake has perfect configuration for sensitive bending and economic solutions.

- Precise results for long and deep bends.

- Continuous sensitivity with crowning system.

- Long lasting rigid body is also suitable for heavy duty applications.

- Easy maintenance.

You can bend longer and deeper parts with maximum repeatability with standard ACCURL-Bend machines.

Standard Equipment

- Height adjustable and movable sliding front support arms.

- Top and bottom tools are surface hardened by special treatment.

- Promecam easy clamping system.

- Delem DA52s CNC controller.

- CNC controlled strong X=800 mm back gauge

- 410 mm throat depth.

- 2 back gauge fingers

- Scales in metric and inches.

- Crowning system in bottom beam 2500/.../4100 hydraulic crowning and from 600 tn and above motorized crowning is standard.

- Foot pedal is produced according to CE standards and suitable for single and multiple bends.

- 2 photocells are placed facing each other for rear guards.

- Covers for cylinders and top beam

- Preadjusted electrical requirements based on customer's geographical area.

Delem DA52s CNC Control system

- Numerical, one page programming

- Quick, one-page programming

- Hotkey navigation

- 6,4" VGA colour LCD (TFT)

- Up to 4 axes (Y1, Y2, and 2 auxiliary axes)

- Crowning control

- Tool/material/product library

- USB, memory stick interfacing

- Servo, frequency inverter and AC control for backgauge axes.

- Advanced Y-axis control algorithms for closed loop as well as open loop valves

Specifications

| Model (SC-MB8) | 63T×1500 | 63T×2500 | 100T×3200 | 100T×4200 | 160T×3200 | 160T×4200 | 250T×3200 | ||

| Capacity | kN | 630 | 630 | 1000 | 1000 | 1600 | 1600 | 2500 | |

| Max. Bending Length | mm | 1500 | 2500 | 3200 | 4200 | 3200 | 4200 | 3200 | |

| Between Columns | mm | 1100 | 2060 | 2700 | 3700 | 2700 | 3700 | 2700 | |

| Max. Shut Height | mm | 430 | 430 | 480 | 480 | 480 | 480 | 480 | |

| Slide Stroke | mm | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| Throat Depth | mm | 370 | 370 | 400 | 400 | 400 | 400 | 400 | |

| Bolster Width | mm | 150 | 150 | 200 | 200 | 200 | 200 | 200 | |

| Down Speed | mm/min | 100 | 100 | 130 | 130 | 130 | 130 | 110 | |

| Pressing Speed | mm/min | 8 | 8 | 10 | 10 | 10 | 10 | 10 | |

| Return Speed | mm/min | 100 | 100 | 125 | 125 | 125 | 125 | 110 | |

| Back Gauge Stroke | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Outline Size | L | mm | 1825 | 2825 | 3500 | 4500 | 3500 | 4500 | 3500 |

| W | mm | 1650 | 1650 | 1650 | 1650 | 1650 | 1650 | 1730 | |

| H | mm | 2600 | 2430 | 2540 | 2540 | 2580 | 2580 | 2580 | |

| Weight | kg | 4600 | 5600 | 8000 | 9500 | 10000 | 12000 | 15000 | |

| Model(SC-MB8) | 250T×4200 | 300T×3000 | 300T×4000 | 300T×6000 | 400T×4000 | 400T×5000 | 400T×6000 | ||

| Capacity | kN | 2500 | 3000 | 3000 | 3000 | 4000 | 4000 | 4000 | |

| Max. Bending Length | mm | 4200 | 3000 | 4000 | 6000 | 4000 | 5000 | 6000 | |

| Between Columns | mm | 3700 | 2500 | 3150 | 5050 | 3150 | 4050 | 5050 | |

| Max. Shut Height | mm | 480 | 480 | 480 | 480 | 480 | 480 | 480 | |

| Slide Stroke | mm | 200 | 200 | 200 | 200 | 320 | 320 | 320 | |

| Throat Depth | mm | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Bolster Width | mm | 200 | 250 | 250 | 250 | 250 | 250 | 250 | |

| Down Speed | mm/min | 110 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Pressing Speed | mm/min | 10 | 8 | 8 | 8 | 8 | 8 | 8 | |

| Return Speed | mm/min | 110 | 85 | 85 | 85 | 80 | 80 | 80 | |

| Back Gauge Stroke | mm | 500 | 500 | 500 | 500 | 500 | 500 | 500 | |

| Outline Size | L | mm | 4500 | 3300 | 4300 | 6400 | 4300 | 5300 | 6400 |

| W | mm | 1730 | 1950 | 1950 | 2000 | 2100 | 2100 | 2100 | |

| H | mm | 2580 | 2670 | 2670 | 2950 | 3100 | 3100 | 3170 | |

| Weight | kg | 17000 | 20000 | 22000 | 30000 | 27000 | 32000 | 38000 | |

Detailed Pictures