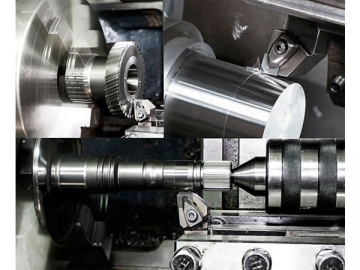

ISO PCBN Indexable Insert

Features of ISO PCBN Indexable Insert

1. With the advantages of high abrasive resistance, high processing precision, good thermal conductivity and long service life, the PCBN insert meets the international standard of ISO.

2. The PCBN insert can realize high speed cutting and hard material cutting with high work efficiency, and also can facilitate fast clamping.

3. Our PCBN insert can be used repeatedly so it can lower your processing cost.

Application

The PCBN insert is used to process hardened steel, hardened cast iron, grey cast iron and iron series metal work pieces.

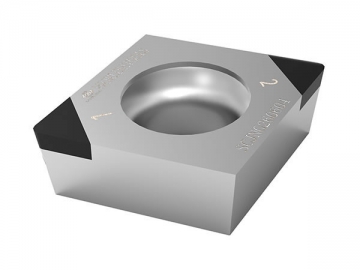

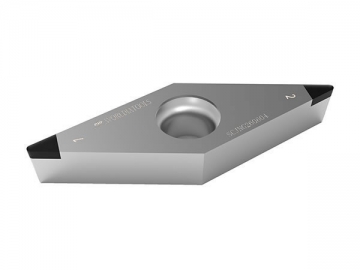

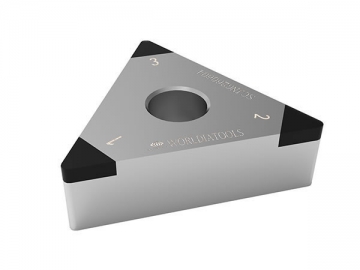

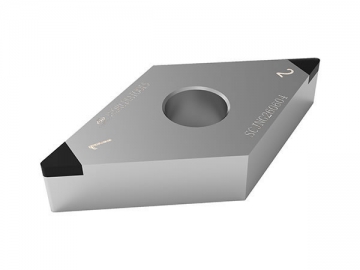

| Standard cutting edge | Sharp Cutting Edge | Strong Cutting Edge |

| S0102505 | S0051502 | S0103505 |

| Shape | ISO | ANSI | Cutting Edge | Tip Shape | Grade | Dimensions in mm | ||||||

| PN311 | PN310 | PN312 | ic | φd | s | r | la | |||||

| CCGW060202-1N | CCGW2(1.5)(0.5)-1N | S0102505 | SLST30S | ● | ● | ● | 6.35 | 2.8 | 2.38 | 0.2 | 3.0 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CCGW060204-1N | CCGW2(1.5)1-1N | S0102505 | ● | ● | ● | 0.4 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CCGW060208-1N | CCGW2(1.5)2-1N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CCGW060202-2N | CCGW2(1.5)(0.5)-2N | S0102505 | SLST30S | ● | ● | ● | 6.35 | 2.8 | 2.38 | 0.2 | 3.0 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CCGW060204-2N | CCGW2(1.5)1-2N | S0102505 | ● | ● | ● | 0.4 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| CCGW060208-2N | CCGW2(1.5)2-2N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T302-1N | DCGW3(2.5)(0.5)-1N | S0102505 | SLST30S | ● | ● | ● | 9.525 | 4.4 | 3.97 | 0.2 | 3.0 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T304-1N | DCGW3(2.5)1-1N | S0102505 | ● | ● | ● | 0.4 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T308-1N | DCGW3(2.5)2-1N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T312-1N | DCGW3(2.5)3-1N | S0102505 | ● | ● | ● | 1.2 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T302-2N | DCGW3(2.5)(0.5)-2N | S0102505 | SLST30S | ● | ● | ● | 9.525 | 4.4 | 3.97 | 0.2 | 3.0 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T304-2N | DCGW3(2.5)1-2N | S0102505 | ● | ● | ● | 0.4 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T308-2N | DCGW3(2.5)2-2N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| DCGW11T312-2N | DCGW3(2.5)3-2N | S0102505 | ● | ● | ● | 1.2 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TPGW090202-1N | TPGW(1.8)(1.5)(0.5)-1N | S0102505 | SLST30S | ● | ● | ● | 5.56 | 2.5 | 2.38 | 0.2 | 3.0 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TPGW090204-1N | TPGW(1.8)(1.5)1-1N | S0102505 | ● | ● | ● | 0.4 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TPGW090208-1N | TPGW(1.8)(1.5)2-1N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TPGW090202-3N | TPGW(1.8)(1.5)(0.5)-3N | S0102505 | SLST30S | ● | ● | ● | 5.56 | 2.5 | 2.38 | 0.2 | 3.0 | |

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TPGW090204-3N | TPGW(1.8)(1.5)1-3N | S0102505 | ● | ● | ● | 0.4 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| TPGW090208-3N | TPGW(1.8)(1.5)2-3N | S0102505 | ● | ● | ● | 0.8 | ||||||

| S0051502 | ● | ● | ||||||||||

| S0103505 | ● | ● | ||||||||||

| SF | SL | SS | CB | CS | SWW | SWU |

| Full Face | Solid Tipped Corner | Solid CBN | Standard Tipped Corners | Standard Full Edge | Solid Tipped Corners Type ‘W’ | Solid Tipped Corners Type ‘U’ |

| ST | WG | CB |

| Nose Radius | Wiper | Chip Breaker |

| Code | Ap | 22 | 25 | 28 | 30 | 40 |

| Size | Ap | 2.2 | 2.5 | 2.8 | 3 | 4 |

| Work piece Material | type | WORLDIA PCBN Grades | Content | PCBN Grade | Bond | Hardness | Characteristics | Applications |

| H | Solid tipped corners | PN311 | 45~50 | 1 | TiC | 2600~2800 | Good thermal stability and crater wear resistance | Used for high-speed continuous turning of hardened steel |

| PN310 | 60~65 | 1~2 | TiCN | 2600~2800 | Combination of wear resistance and thermal stability | Used for moderately interrupted and continuous turning of hardened steel | ||

| PN312 | 65~70 | 1< | TiN | 2700~2900 | High degree of toughness due to fine CBN and ceramic binder matrix | Used for heavy interrupted turning of hardened steel |

Material

The tool tip uses premium PCBN blanks manufactured by world famous companies.

The substrate uses high quality tungsten carbide.

We are a professional PCBN insert manufacturer in China. We offer various types of products such as PCD/PCBN boring cutter, PCD reamer, high penetration diamond scribing wheel, and tungsten carbide supported diamond die blanks.