Extrusion Blow Molding Machine

(Geomembrane Film Extruder)

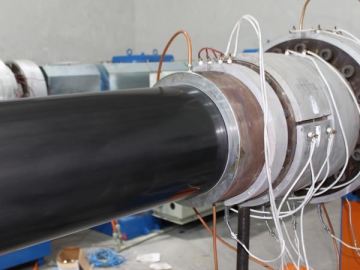

The extrusion blow molding machine, as a kind of blown film extrusion line, is mainly used for producing three-layer wide impermeable composite film, geomembrane. The main components of this plastic blow molding machine include three plastic film extruders, hydraulic rapid screen changing machine, three-layer composite spiral mold, air ring with two air outlet, traction machine, coiling machine, and temperature and electronic component controlling system.

Feature of the extrusion blow molding machine

1. Special blown film extruder and screw are used. The plastification and production capacity are both enhanced. The extrusion machine can be moved as one piece, making the position adjustment quite easy.

2. The special triple-layer spiral mold allows the extrusion blow molding machine to produce both greenhouse film and geomembrane film.

3. A hydraulic screen changing device is used. It can operate when the extruding line is working.

4. To improve the film product, we use the IBC inner cooling control system and two-outlet air ring for our extrusion blow molding machine.

5. The traction machine is controlled by a frequency conversion motor, and comes with a pneumatic clamping mechanism. Thus the upward traction and coiling machine can be controlled at the same time.

6. The roller of the coiling machine has a large frictional coefficient, whit which the film can be easily collected.

| Model | ||

| Film width (mm) | 6000 | 8000 |

| Film thickness (mm) | 0.3-2 | 0.3-2 |

| Film layer | 3 | 3 |

| Suitable raw material | LDPE, LLDPE, EVA, MLLDPE, HDPE | |

| Max. output (kg/h) | 1500 | 2400 |

| Extruder | Ф150/30×3 | Ф180/30×3 |

| Main motor (kW) | 250×3 | 280×3 |

| Mold diameter (mm) | Ф1800 | Ф2400 |

| Air ring diameter (mm) | 3600 | 4500 |

| Traction height (mm) | 21000 | 24000 |

| Traction speed (mm) | 3-30 m/min | |