Plastic Blown Film Line

(Greenhouse Plastic Film Extruder)

The plastic blown film line can be used to deal with various materials like LDPE, LLDPE, EVA, mixture of LDPE and LLDPE. It is a popular selection of plastic film extrusion blow molding machine for production of greenhouse plastic film.

Main components of the plastic blown film line

1. Material feeding machine

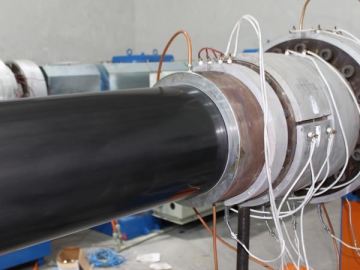

2. Plastic film extruder (plastification)

3. Mold (shape forming)

4. Traction rack (cooling and shape-forming)

5. Traction machine

6. Coiling machine

Feature of the plastic blown film line

1. The extrusion equipment comes with mixing screw and mixing head, powerful conveying lining, and DC motor (or frequency conversion motor).

2. The cooling system comes with a low wind pressure and large air flow volume fan.

3. A stable and reliable traction system and a subdivision device are available.

4. An inner cooling device is optional for the blown film machine.

| Model | |||

| Extruder | 150/30 | 180/30 | 200/30 |

| Main motor (kW) | 250 | 280×2 | 315×3 |

| Mold diameter (mm) | Ф 1400 | Ф 2000 | Ф 2600 |

| Extruding capacity (kg/h) | 500 | 700×2 | 1000×3 |

| Traction speed (m/min) | 20 | 20 | 20 |

| Traction height (mm) | 17000/19000 | 24000 | 30000 |

| Length of guide roller (mm) | 2800 | 4500 | 5500 |

| Max. film width (mm) | 10000 | 16000 | 20000 |