Pulp Plate Forming Machine

Application

Pulp plate forming machine can be used to produce the degradable food packaging product using plant fiber (including sugarcane, bamboo pulp, wheat straw and wood pulp) as raw material. Those products can be used in microwave oven, oven, and also can refrigerate preservation and steam food.

We have 6 different types for choose, our machine, through different mold can produce different pulp product. Detailed data please click the follow model:

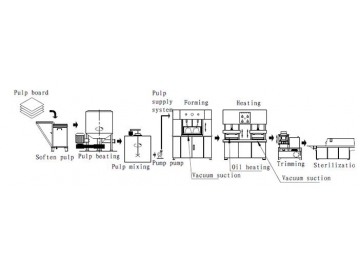

Production process analysis

The production line of the pulp plate forming machine is composed of five main processes: pulping, forming, modeling, cutting edge disinfection and finished packaging. See the process flowchart below.

1. The pulping process is to make the quantitatively soaked pulp plate into paper pulp. The first step is finished by hydraulic pulping machine and let the pulp into the tank, adding edible grade waterproofing and anti-oil additives, and then into the pool.

2.The pulp is send to the automatic molding machine for precise quantitative grouting, and then use the hydraulic stir mix the pulp, then vacuum dehydration.

3. After modeling, those tableware are manually transferred to the thermostatic solidified mold for dehydration and solidification.

4. The molded semi-finished product will be transferred for cutting edge finishing and inspected to meet the factory requirement, disinfection and packaging into the warehouse.