Guardrail Forming Machine

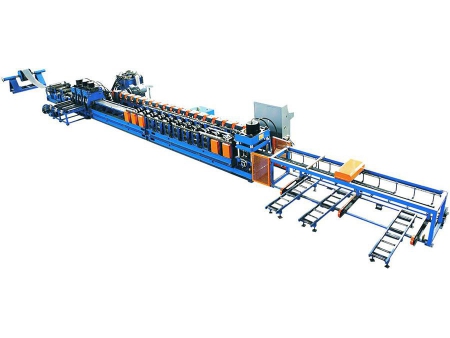

Guardrail Forming Machine HL-310

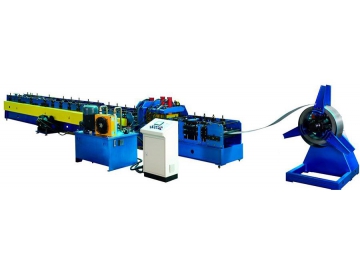

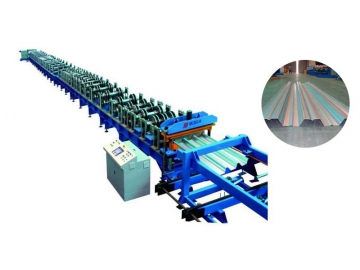

Our automatic guardrail forming machine integrates cold bending, cold stamping, auto stacking, and auto control technologies. The hot rolled steel strip is leveled and punched by the machine then roll formed and cut into highway guardrail. High production efficiency, high level of automation and low labor intensity are the main features of this machine.

Main Components

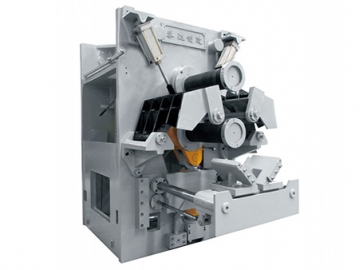

Jinggong guardrail forming machine is made up of a decoiler, leveling system, trimming rewinding system, cutting equipment, punching system, roll forming system, shearing device, automatic stacker, electric control system, hydraulic system, and automatic control system.

| Item | Parameter | |

| Suitable material | Type | Hot rolled plate, galvanized plate |

| Plate strength | ≤350 MPa | |

| Plate thickness | 3-4 mm | |

| Coil inside diameter | 500, 600 mm | |

| Coil weight | 10 T | |

| Working speed | ≥20 m/min | |

| Roller material | D2 quenching treatment | |

| Driving mode | Gearbox drive | |

| Console mode | Touch screen+ button | |

| Total power | About 90 Kw | |

| Electric control system | Industrial computer PLC frequency control | |

| Outline dimensions (LXWXH) | 30X4X1.7 m | |

Founded in 1968, Jinggong Science & Technology is a China guardrail forming machine manufacturer and supplier. We can not only provide guardrail forming equipment, but also offer many other kinds of construction materials machinery such as sandwich panel machine, purlin forming machine, and roll forming machine etc. Our products are ISO9000 and CE compliant. If you are interested in our product, please feel free to contact us.