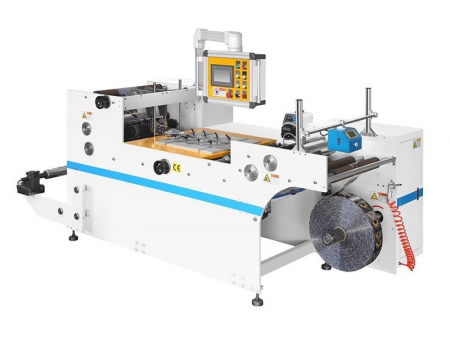

Moldless Shrink Sleeve Seaming Machine, ZHA-300

Request a Quote

The ZHA-300 shrink sleeve seaming machine is a converting machine used to produce shrink sleeve labels for various products. This shrink sleeve label production machine can accomplish automatic size adjustment without the need for mold, it is ideal to accommodate the specific needs and budgets of customers.

Specifications

Details

| Model | |

| Width of unwinding | 620mm |

| Diameter of unwinding | Ø600mm |

| Diameter of rewinding | Ø700mm |

| Min. sealing size | 60mm |

| Max. sealing size | 300mm |

| Max. seaming speed | 300m/min |

| Mechanical speed | 330m/min |

| Machine voltage | 220V/50Hz |

| Overall dimensions | 2850mm×1600mm×2100mm |

- Entire machine view

- Mold-less forming plate

- Copper tube gluing part

- Rewind load cell

- Pulling roller load cell

- Unwind load cell with EPC device

- USA Nordson needle gluing system (optional)

- BST shrink sleeve width measuring system (optional)

- Rewind oscillation device for producing high quality rolls

- Heavy-duty frame with robust structure enables the shrink sleeve seaming machine to run stably and smoothly at high speed of up to 300m/min;

- The use of adjustable forming plate allows for more efficient work;

- Automatic solvent feeding system for precise control of solvent applying;

- Automatic tension control ensures optimal unwind and rewind tension;

- EPC edge guide system is imported from world's well-known brand, with 0.1mm precision;

- Accurate product width is guaranteed;

- Cantilevered rewind and unwind shafts are used for quick roll changeover;

- PLC with color touch screen control system;

- Needle gluing system works with glue pump and PLC to assure accurate control of glue applied in accordance to the machine speed;

- Rewind comes with oscillation device for producing high quality rolls;

- Static eliminator is employed prior to rewinding;

- Outstanding performance is well maintained due to 4 servo motors;