Self-Unloader Bulk Carrier Discharging Conveyor

We are a metal welded structure manufacturer backed by extensive processing strength and machining expertise for marine bulk conveyance equipment. Due to this, we have been working with EMS TECH INC. in Canada since 2010, and delivered more than 20 sets of self-unloader systems.

Gravity type self-unloader

Design organization: EMS-TECH INC, Canada

Drawings refining and manufacturer: SDHM Heavy Machinery

Customers: CSL Canada, Algoma, E.O. Oldendorff Germany, CSL Australia, Van Oord Holland, Vulica America, JK Express Korea

Equipment unloading capacity: 10Kt/h above

Explanation

The self-unloading vessel system was designed by EMS-TECH, and is capable of unloading various granular and other large material cargos, with a maximum conveyance of massive material of about 350mm in size. The system can be installed on the top of bulk carriers over 100K, and the unloading speed can reach more than 10Kt/h.

Working principle

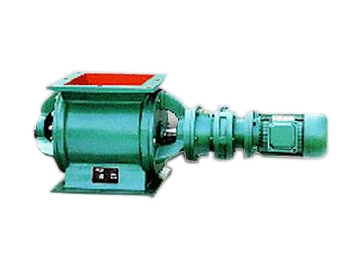

The materials enter the belt conveyor system through the sluice gate from the bottom of the bulk carrier, and then, through the C type hoister, they are dropped into the main deck unloading boom (according to the difference of the specific environment, the booms have 30 meters, 50 meters, 80 meters, 90 meters, 45±15 meters, 60±20 meters and other different specifications), and finally conveyed via the unloading boom to the dock or the upper side of shallow draft barge to complete the unloading operation. The biggest feature of the self-unloading system is that it is not restricted by the operating conditions of the wharf and can unload goods independently.

Product details

Because the self-unloading vessel system operates in cold sea areas, we used high strength steel, with a low temperature impact resistance up to -20 degrees centigrade. In order to reduce the weight of the equipment, EMS-TECH INC utilized a lightweight design for the unloading boom, and with the high strength steel tube truss with an extremely thin tube wall, welding difficulties were improved during the manufacturing process. Through the efforts of our technical personnel, each unloading boom provided by us meets all customer and ship owner requirements.

Self-unloader with deck crane

Design organization: EMS-TECH INC, Canada

Drawings refining and manufacturer: SDHM Heavy Machinery

Customers: CSL Canada, Algoma, E.O. Oldendorff Germany, CSL Australia, Van Oord Holland, Vulica America, JK Express Korea

Equipment unloading capacity: 1500t/h ~ 3000t/h

Explanation

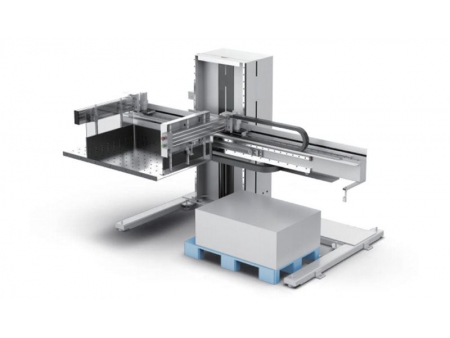

The self-unloading ship system grabs the bulk materials from the mother ship cargo holds using the German Liebherr crane installed on the deck of the bulk carrier, and places them in the 5~6 large hoppers attached on deck. Then, through the gate designed by EMS-TECH, the bulk materials are released on the belt conveyor, and transported via the unloading boom to the receiving device on shore or stored inside small barges.

In order to reduce the movement of the ship, EMS-TECH INC designed the 65m±25m telescopic unloading boom with the tube truss structure. By using high strength seamless steel tubes, the weight of the boom is reduced and the delivery efficiency of the equipment is thus significantly improved.

Here is a project of our self-unloader bulk carrier discharging conveyor, and our company provides all kinds of custom steel structures for heavy equipment. We have supplied large welded steel structures like bulk carrier structure, offshore structure, marine steel structure for many brand companies. By using quality raw materials and complete manufacturing equipment, we offer quality heavy duty steel structures for global customers.