Fully Automatic Loader & Unloader

Request a Quote

Fully Automatic Loader & Unloader

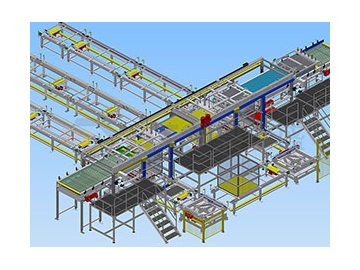

Automatic loader/unloader system is developed in response to the market needs of continuous loading and conveying of the products, aiming at providing stable and reliable operation, as well as high working efficiency. DTS specializes in the R&D, production and commissioning of loading and unloading system for retort sterilization. We can also make reasonable layout according to the different situations and needs of customers.

Application

Glass bottles, tin cans, PE cans, two-piece cans, three-piece cans

Working Principle

- Packaged products are transported by the conveyor system into the basket loader for orderly stacking.

- Basket conveyor automatically delivers the baskets into the retorts.

- The sterilized products are conveyed to the unloader for automatic unloading.

- The unloaded products are transported automatically to the packaging equipment for testing and packaging.

Features

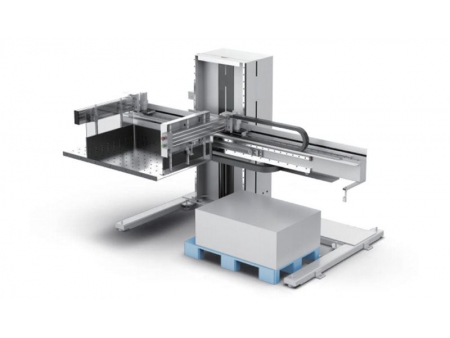

- Hydraulic lifting system adopts two-stage scissor lift platform.

- Automatic loader/unloader system adopts pneumatic clamping mechanism to avoid products falling or upside down during transportation.

- Germany PIAB vacuum gripper system ensures stable running and continuous operation, achieving fully automatic unattended operation.

- Only 1 operator is enough to operate the entire loading/unloading system, capable of accomplishing a working efficiency of 5 layers per minute. The equipment runs stability, reliability and high working efficiency.

Leave Your Message

Related products

Send Message

Most Recent

More

Other Products

Videos