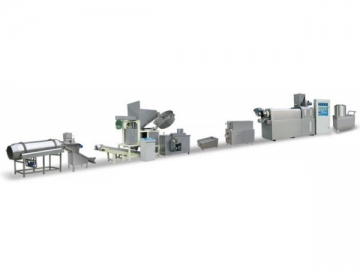

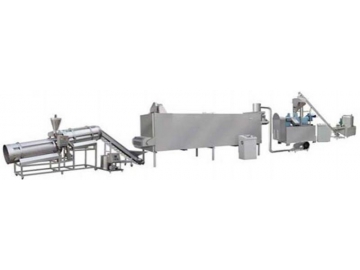

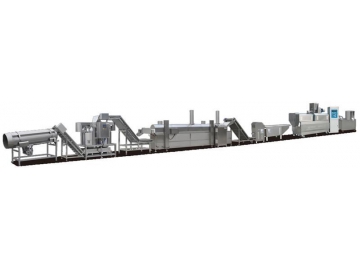

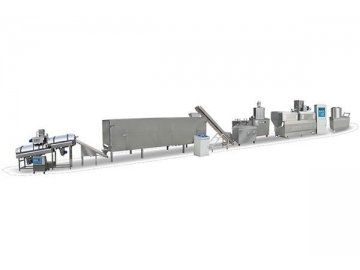

Crispy Snack Manufacturing Line (mixer, extruder, deep fryer, seasoning, coating)

Introduction of the crispy snack manufacturing line (mixer, extruder, deep fryer, seasoning, coating)

This production line is d designed to produce thinly sliced foods in various shapes such as triangles, circles, and hexagons. It is typically used on corn starch and rice flour based products for extrusion and roll shaping.

| Model | Installed Power | Actual Consumption | Throughput | Dimension | |

| SX65-IIIA | 35KW | 28KW | 120-150Kg/h | 25x1.0x1.8m |

- The crispy snack manufacturing line is controlled by a highly automatic PLC system which can be operated by just 2 workers.

- The throughput of the line can reach as high as 100-500 kg/h.

- The line is controlled by a highly energy efficient frequency control system.

Equipment flowsheet

Flour mixer → Food process extruder with single screw/ twin screw → Post-extrusion cutter → Cooling bed → Automatic fryer → Automatic seasoning line

Main equipment

SX3000-100 food process extruder with single screw

Introduction

It is made up of a feeding system, extrusion system, rotary cutting system, heating system, transmission system, cooling system and control system and mainly used to produce fried foods.

- The screw, cylinder, mold are all designed with a circulating cooling system so raw materials can maintain temperature stability during extrusion.

- The screw is made by a special process making it wear and bend resistant for maximum durability.

| Model | Installed Power | Actual Consumption | Main Motor Power | Throughput | Dimension | |

| SX3000-100 | 45KW | 28KW | 30KW | 80-100Kg/h | 3.5x1.05x1.96m | |

| SX200-90 | 45KW | 30KW | 30KW | 80-100kg/h | 3.2x1.05x1.96m |

LXZG-2500 Continues Automatic Fryer

Introduction

The LXZG-2500 continues automatic fryer consists of a wire mesh belt conveying system, automatic lifting system, automatic filtering system, oil temperature automatic control system, automatic oil filling system, heating system. It can operate completely automatically using many heating methods like coal, gas, fuel and electric.

- Automatic filtration system of the fryer can clean the oil residue during operation, so it can ensure frying is of high quality.

- The automatic lifting system makes cleaning and maintenance of the fryer much more convenient.

| Model | Installed Power | Actual Consumption | Main Motor Power | Throughput | Dimension | |

| SX65-IIIA | 35KW | 28KW | 22KW | 120-150kg/h | 2.5x1.0x1.8m | |

| SX65-IIIB | 60KW | 40KW | 22KW | 150-200kg/h | 3.5x1.0x1.8 | |

| SX85-II | 120KW | 60KW | 90KW | 300-500kg/h | 4.0x1.2x3.0 | |

| SX65-I | 70KW | 40KW | 30KW | 100-150kg/h | 3.5x1.0x1.8 |

TWD-I single roller seasoning machine

Introduction

TWD- I can be used to season all kinds of puffed and fried food or inject oil and sugar.

- It is equipped with an elevator to feed automatically optimizing efficiency.

- It is equipped with an imported fuel injection head which can spray evenly and adjust the amount of the oil.

| Model | Installed Power | Throughput | Dimension | |

| TWS-I | 2.2KW | 180-250kg/h | 3.6x0.9x1.7m | |

| TWD-I | 0.75KW | 150-200kg/h | 2.1x0.7x1.6m | |

| TWB-I | 0.75KW | 150-200kg/h | 1.4x1.1x1.6m |

Index

food processing equipment, commercial food machines, food manufacturing line, puffed food machines