Corrugator Stacker for corrugated cardboard production

Request a Quote

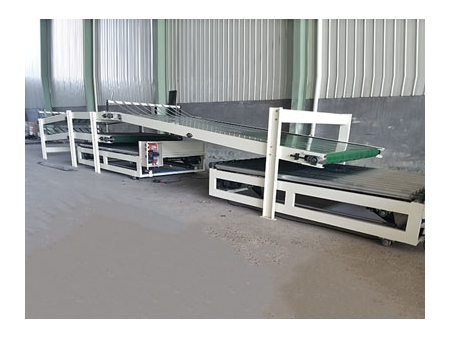

Right-angle Stacker

- Huatao’s right-angle stacker is constructed with welded 14# channel steel, it allows electric adjustment of paperboard dimension, and pneumatic control of horizontal paperboard conveying, whose conveying speed is electronically adjustable;

- When the amount and height of paperboard meet the set value, foot switch can be applied to unload the paperboard;

- Wide-size paper conveying and flat belt conveying are adopted;

| Working Width | 1000-2200 mm |

| Design Speed | 150 m/min |

| Working Speed | 120 m/min |

| Max. Length of Stacking | 3500 mm |

| Max. Height of Stacking | 250 mm |

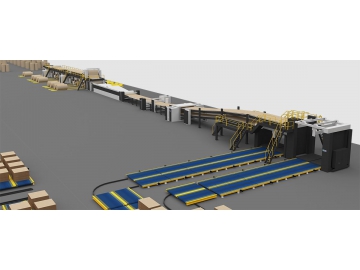

Gantry Stacker

- Gantry stacker features short order change time of 5 seconds, automatic counting, horizontally unloading and automatic changeover;

- When stacking reaches set amount, the variable frequency control enables the gantry stacker to achieve stable and horizontal unloading for corrugated cardboard;

- The position of back gauge is AC servo controlled, so the automatic, fast and accurate changeover can be ensured;

- Back gauge of this gantry corrugator stacker can be automatically moved, quite suitable for small order production;

- Horizontal belt type stacking station and the AC servo controlled lifting device ensure that cardboards are stacked in a stable and orderly manner;

- Conveying belt is equipped with electric conveying rack and dual-station table;

- Color touch screen is used for easy on-site operation;

- This gantry stacker is fully automatic controlled, so a high efficiency and low labor cost are guaranteed;

| Working Width | 1600-2500 mm |

| Design Speed | 250 m/min |

| Working Speed | 220 m/min |

| Max Length of Stacking | 3500 mm |

| Max Height of Stacking | 250 mm |

Basket Stacker

- Automatic stacking and unloading, automatic positioning of back gauge, and automatic horizontal stacking are all available;

- Servo controlled lifting basket ensures smooth, fast, and reliable operation;

- This basket type corrugator stacker features five-section belt conveying, which are controlled independently by variable frequency motors. In this way, automatic and accurate counting, as well as smooth conveying can be achieved;

- PLC control system enables automatic production tracking, paperboard discharging, basket lifting, back gauge positioning, automatic batching and stable stacking;

- Multiple sets of fiberglass hold-down brushes are used, which can be adjusted in accordance with the cardboard length;

- Human-machine interface display is used to set data, which is fast and easy operated;

| Working Width | 1600-2500 mm |

| Design Speed | 250 m/min |

| Working Speed | 220 m/min |

| Max Length of Stacking | 500-3500 mm |

| Max Height of Stacking | 1800 mm |

Related products

Send Message

Most Recent

More

Other Products

Videos