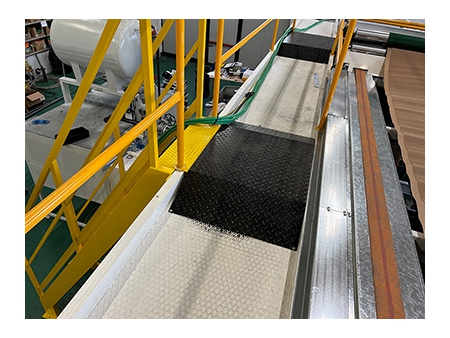

Corrugator Bridge

Request a Quote

Corrugated Board Manufacturing

Overhead Bridge

Duplex Bridge

-

- Design speed

- 100m(3937.01")/min-250m(9842.52")/min

-

- Working width

- 1400mm(55.12")-2500mm(98.43")

-

- Guide precision

- ±3mm (0.12")

Features

- The unit precisely conveys single-faced corrugated paper by conveyor belt to the bridge brake;

- Individual variable frequency motor with lifting structure, PVC conveyor belt, the wave overhead corrugated board is overlapped to convey;

- The surface of all rollers is hard chromium plated after grinding; Control the vacuum absorption tension, 5-inch absorption tube, plus adjusting valve, air flow regulation with continuous variability;

- Electrical guiding device II, positioning is controlled by guiding board with two pedals, screw transmission, fast and accurate positioning, stable operation.

- 3kW centrifugal fan with inverter is used for corrugated paper tensioning with vacuum absorption method, electric web guiding system accurately aligns the corrugated paper to assure smooth surface;

- Rewind station is equipped with independent variable frequency drive which controls the singer facer speed to keep an amount of corrugated boards on the bridge, thus compensating the varying speed of corrugating line while allowing double facer to run at different speeds from the single facer;

- Bridge riser (incline conveyor) adopts two sets of inclined conveyor belts to lift single-faced corrugated paper to the bridge where it is deposited in loops, permitting the storage of a large quantity of single-faced corrugated boards;