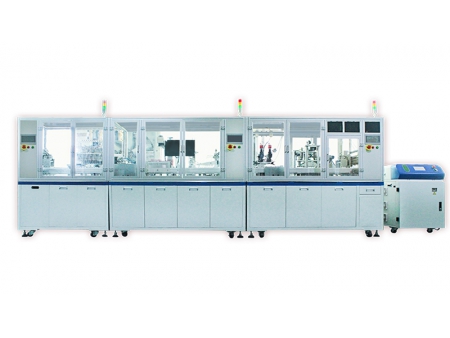

LD-12A-1560 Automatic Molded Pulp Packaging Machine

Description

LD-12A-1560 automatic molded pulp packaging machine can achieve processes of automatic water feeding, automatic pulp feeding, pulp mixing, vacuum blank forming, heat pressure forming and ejection counting.

Application

LD-12A-1560 automatic molded pulp packaging machine uses Siemens PLC system to control production process. Action data can be monitored and adjusted via touch screen. LD-12A-1560 automatic molded pulp packaging machine produces microwavable, freezable and distillable food packaging products including plates, bowls, trays, cups and mugs from plant fiber pulp including bagasse pulp, bamboo pulp, wheat straw pulp, reed pulp and wood pulp. Besides, it can also produce industrial packaging products.

- Plate

- Bowl

- Box

- Tray

- Cup

- Slipper

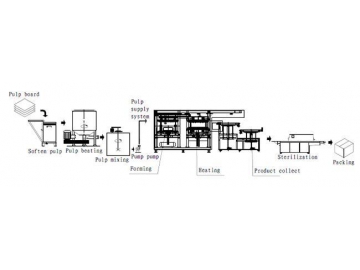

Manufacturing Process Detail

1. Pulping process takes soaked paper pulp boards and mixes them into pulp. Firstly paper boards are shredded by hydraulic pulper and taken into pulp mixing pool. After adding eatable waterproof, oil proof additives, they are taken into pulp feeding pool. They are then fed via feeding system to the automatic quantitative analyzer in the forming machine. After accurate slip casting, pulps are then stirred evenly with water and then dehydrated and formed.

2. Blank forming process is the most important process in the production line. Pulps are slip casted, stirred evenly with water and then dehydrated. Latest dual-vacuum-dehydrating trim-free technology in the forming mold raises qualified rate by eliminating perforation and uneven thickness. Formed product and then moved to solidifying mold for further dehydration.

3. Heating process employs patent-protected technology from our company. Compared to traditional electrical heating technology, it is 70% more energy effective and 30% more cost effective. This technology meets FDA、SGS、BPI international food packaging health standards and Chinese health standards.

4. No further trimming process is needed after heating. Products can be directly sterilized and packaged. This is more effective, while guaranteeing a 98% qualified rate as well as a high production capacity and a very good quality.

Specification| Item | Parameter | Comment |

| Dimension | 8000*2420*3750mm | Provide by manufacturer |

| Weight | 18.5T | Provide by manufacturer |

| Workbench dimension | 1560*1560mm | Provide by manufacturer |

| Loading capacity | 7.25KW | |

| Loading time | 45s | Calculated by standard 9-cun plate (16g) |

| Control range of product weight | ±1.5-2.5g | Standard weight ±1.5-2.5 |

| Maximum power of heat pressing mold | 200KW | Provide by manufacturer |

| Product height | ≦100 mm | |

| Production Capacity Daily | 1100KG (60000) | Calculated by standard 9-cun plate (16g) |

| Qualified rate | ≧95%s | Meets standard |

Configuration

LD-12A-1560 consists of an automatic pulp molding and forming unit, a forming pulp pool, a dual-vacuum dehydrating unit, a trim-free unit, a hydraulic heat pressing unit with heat transfer oil, a manipulator, an energy-saving hydraulic device and a PLC control system.

The system is programmable. Automatic water feeding, automatic pulp feeding, automatic mixing, heat pressure drying and ejection counting can all be programmed.

Automatic product collecting unit consists of an optical fiber alarming unit which monitors the transferring of pulp product and a transferring unit.

These devices are directly connected to computer control system, realizing automatic stopping and alarming function.

Feature

1. Pipes, valves of LD-12A-1560 automatic molded pulp packaging machine are made of 304 steel, which has very good erosion-proof, thermal insulation capabilities.

2. Mold is made of 7075 aluminum materials with very high heat transfer coefficient, very high anti-wear capabilities and very good conducting ability.

3. Patent has been granted for the unique technology applied in the machine.

4. There are 2 heating methods for this machine, via electricity or via heat transfer oil.

5. Hydraulic pressure can be applied up to 15MPa. High pressure would result in producing products with high density and high strength.

6. Safe rate for the machine is 95%. LD-12A-1560 automatic molded pulp packaging machine is capable of operating non-stop 24 hours a day.