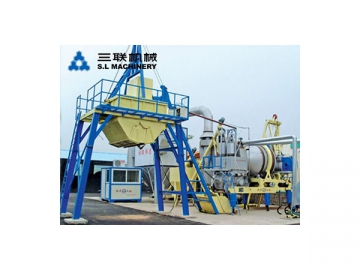

Asphalt Mixing Plant (Mobile)

In addition to stationary structure, Sanlian is also proud to supply an array of asphalt mixing plants in mobile designs for smaller production capacity but high flexibility and efficiency. Our mobile asphalt plants cover the range of 20t/h, 30t/h and 40t/h. Using this construction equipment, minimum site work is needed in order to erect the plant. The complete asphalt production process is monitored and controlled by user friendly and intuitive computer control system. Contact us today to improve your working efficiency with our mobile asphalt mixing plants.

The QLB20 mobile asphalt mixing plant is a new type asphalt plant with new designs including central-flip over loading device, central introduction of air and double roller structure. It ensures flexible transfer and minimum site requirement as well as quick measurement, accurate proportion and reliable product quality. The mobile construction equipment is an ideal solution for road construction and daily maintenance of asphalt pavements.

Technical Parameters of the Mobile Asphalt Mixing Plant| Model | ||

| Productivity (t/h) | 20 | |

| Total Power (kW) | Fuel | 46.5 |

| Coal | 70 | |

| Discharge Temperature | 130-160 ℃ | |

| Fuel Consumption (kg/t) | Fuel 6.5-7.5kg/t, Coal 13-15kg/t | |

| Optional | Batching mixer, Finishing material hopper, Coal mill, Water dedusting unit, Sack dedusting unit, Control room, Asphalt heating tank | |

| Note: Total powers vary according to different configurations. | ||

With up to 30t/h production capacity as well as some special designs, our QLB30 mobile asphalt mixing plant is widely used for road construction and asphalt pavement maintenance applications. Specifically, the road machinery is designed with central-flip over loading device, central introduction of air and double roller structure. The hot mix asphalt plant is characterized by flexible transfer and minimum site requirement as well as quick measurement, accurate proportion and reliable product quality.

Technical Parameters of the Mobile Asphalt Mixing Plant| Model | ||

| Productivity (t/h) | 30 | |

| Total Power (kW) | Fuel | 100 |

| Coal | 120 | |

| Discharge Temperature | 130-160 ℃ | |

| Fuel Consumption(kg/t) | Fuel 6.5-7.5kg/t, Coal 13-15kg/t | |

| Optional | Batching mixer, Finishing material hopper, Coal mill, Water dedusting unit, Sack dedusting unit, Control room, Asphalt heating tank | |

| Note: Total powers vary according to different configurations. | ||

The QLB40 asphalt mixing plant in mobile construction is able to produce 40t high quality asphalt in an hour. It is ideal road equipment designed for road construction and daily maintenance of asphalt pavement. The new type asphalt plant come with a number of new designs including central-flip over loading device, central introduction of air and double roller structure. It ensures flexible transfer and minimum site requirement as well as quick measurement, accurate proportion and reliable product quality.

Technical Parameters of the Mobile Asphalt Mixing Plant| Model | ||

| Productivity (t/h) | 40 | |

| Total Power (kW) | Fuel | 115 |

| Coal | 135 | |

| Discharge Temperature | 130-160 ℃ | |

| Fuel Consumption(kg/t) | Fuel 6.5-7.5kg/t, Coal 13-15kg/t | |

| Optional | Batching mixer, Finishing material hopper, Coal mill, Water dedusting unit, Sack dedusting unit, Control room, Asphalt heating tank | |

| Note: Total powers vary according to different configuration. | ||