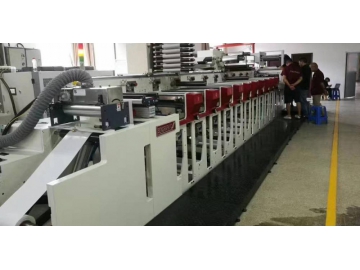

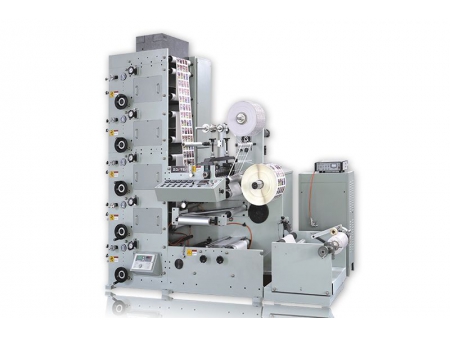

8-Color Stack Flexographic Printing Machine

Acceptable Printing Materials of the Eight-color Stack Flexographic Printing Machine

LDPE: 50 ~ 160μm

LLDPE: 48 ~ 158μm

HDPE: 50~ 162μm

PVC: 50 ~ 160μm

CPP: 48 ~ 165μm

PP: 50 ~ 165μm

NY: 48~ 165μm

PETP: 40 ~ 168μm

OPP: 40 ~ 165μm

BOPP: 40~ 160μm

OPA: 40 ~ 165μm

Plating film: 40~ 170μm

Aluminum: 45 ~ 165μm

Cellophane: 35 ~ 180g/m2

Paper: 35~ 180g/m2

Wrapping paper: 35 ~ 180g/m2

Features of the Eight-color Stack Flexographic Printing Machine

1. The printing machine have one unwinder and one rewinder.

2. Slow speed and full load startup; stable running by auto tension control can decrease noise when increasing or decreasing speed.

3. High dots presentation rate; clear and vivid stratification of screen printing; strong stereo effect and accurate registering.

4. Aluminum roller adopts the Japan semi-sealing small bearing; flinty oxidation, static and dynamic balancing treatments are conducted; low resistance and small flop.

5. Adopted special modulus angular gears, so the printing machine can provide accurate printing size and full printing specifications.

6. With the air exhaust, blowing and heating settings; the heating system adopts the central thermostatic control system and group management, also with the cold air forming devices.

7. When the machine is stopped working, printing rolls can still keep moving.

8. Air shaft is used in material holder.

9. The chamber doctor blade system contains ink container and circulating pump.

10.Plastic roller and grain roller are used to smearing the ink.

11.Accurate printing size can be presented by the special vertical gear transmission device.

12. The machine is equipped with blower and heater; and the heater employed central constant temperate controlling system.

13.Germany particular steel material processed bottom roller: The grouped and controlled bottom roller is processed with special techniques and electrically gilded with 0.1mm hard chromium protective layers.

14. The unwinder has auto deviation correction system.

15. One set of printing cylinder (size: 15 inches)

| Printing color | 8 colors (Reversible printing 8 color press for 1 7, 2 6, 3 5, 4 4, 8 0 ) |

| Printing width | 1000mm |

| Web path width | 1050mm |

| Printing length | 190 ~ 1016mm (7.5"~ 40") |

| Highest machine speed | 90 meters per minute |

| Highest printing speed | 60 meters per minute |

| Plate thickness | 2.28mm |

| Ceramic anilox | 200LPI 2PCS Japan 300LPI 2PCS Japan 500LPI 4PCS Japan |

| Register precision | Longitude ±0.15mm Transverse ±0.15mm |

| Unwind reel diameter | Φ600mm |

| Rewind reel diameter | Φ600mm |

| Unwind | 2PCS |

| Rewind | 2PCS |

| Tension scope | 3 ~ 50kg |

| Tension precision | ±0.3kg |

| Unwind and rewind web cylinder | Φ76mm (inner diameter) |

| Unwind and rewind material holder | Air shaft |

| Press power | Mechanic control |

| Inking | Auto cyclic system, one diaphragm pump |

| Inking distributing | deceleration motor (reduction ratio 1 : 50) |

| Drying model | Electric heating /Infrared(hot air) |

| Bearing: | NSK (Japan) |

| One direction bearing | ASNU (Germany) |

| Drying power | 26kw |

| Air blower (large) | 1.1kw / 4 pcs |

| Air blower (small) | 1.5kw / 2 pcs |

| Master motor power | 7.5kw (reduction ratio 1 : 5) |

| Machine power | 42kw |

| Outline dimension | 5.4m×2.4m×3.3m |

| Deviation correction system | Auto hydraulic pressure |

| Power | Voltage 220/380V, 3 PH, 60/50 HZ |