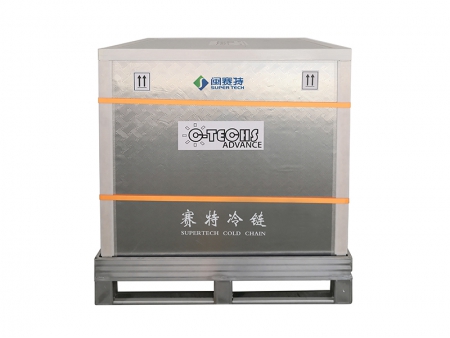

Vaccine Insulated Pallet Shipper

Large capacity, easy assembly and disassembly, folding and recycling

Specifications

- Product Name: Insulated Pallet Shipper

- External Size (mm): 1100*1020*1180

- Internal Volume (L): 993.6

- External Volume (L): 1324

- Box Weight (kg): 64.8

- Panel Stacking Height: 300mm

- Performance (h): 0~5℃ 200h 2~8℃ 160h

- Remark: Easy assembly and disassembly; repeated use

What the Features of Vaccine Insulated Pallet Shipper

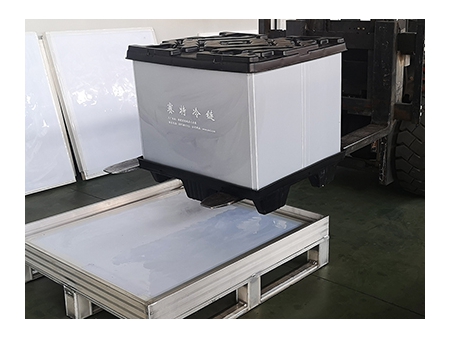

- Lower Logistics Recycling Costs

This insulated pallet shipper can be divided into six pieces of insulation boards and stack together when recycled or not used. In this way, two thirds volume is reduced. The logistic cost reduction is obvious for clients when purchasing or recycling this product.

- Simple Cargo Handling Process

When loading the goods, the forklift can be used to directly place the goods with the pallets in the bottom of the shipper in any direction, and then assemble the insulated pallet shipper with insulation boards. Same way to be used when unloading goods, which greatly reduces the labor cost.

- Unique Ice Box Fixing Bracket

Using a special ice box fixing bracket and making full use of the existing ice box to form a large ice box to match the large box, no need to open mold and easy handling.

- Customizable Size Design

The insulated pallet shipper is produced by our unique modular production process, which can be designed in various sizes and surface material appearance according to customer requirements, no need to open mold.

- Excellent Insulation Barrier Performance

The insulated pallet shipper is produced by our unique modular production process, which can be designed in various sizes and surface material appearance according to customer requirements, no need to open mold.

Applications

The insulated pallet shipper can be used in the cold chain transportation of biological agents, medicine, vaccines, fresh food and other fields.