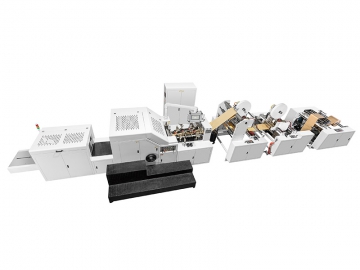

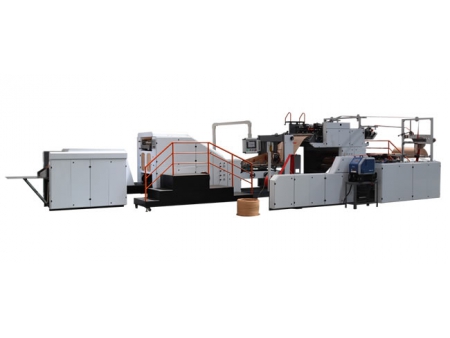

Block Making Machine, Q(F)T6-15

Descriptions

1. The Q(F)T6-15 model of block making machine is designed to make all size of solid blocks according to customers' requirements.

2. It applies PLC control system to realize easy operation.

3. Multi-language options make it suitable for users in various countries.

5. Operators can carry out communication with the solid block making machine easily. This allows for program management.

6. The solid brick making machine is equipped with a Digital Control Panel:

-- It is a new electrical control and fault diagnostic system:

-- The operator can monitor and control the machine through the control panel;

-- The touch screen allows users to set the machine to the desired operating sequence;

-- Pre-vibration times, final vibration time and the number of tamps are changed automatically;

-- If the machine stops, the screen will show where the stoppage has occurred and also the description of the fault.

Raw Materials

Crushed stone, sand, cement, dust and coal, fly ash, cinder, slag, gangue, gravel, perlite and other industrial wastes

Features

1. The block making machine is capable of producing solid concrete blocks in diverse sizes by changing moulds.

2. Some waste materials are used as raw materials to produce solid bricks, thus saving energy and ensuring outstanding environmental performance.

3. Automatic charging of materials can enhance the strength and density of finished blocks.

Applications

The building machinery being introduced here has found wide application in building, road paving, landscaping and other construction fields. It can make various types of concrete blocks including Solid, hollow and cellular blocks, paving stones, garden and landscaping products, slabs, curbstones, grass blocks, slope blocks, interlocking blocks, etc.

| Type | |||

| Exciting Force (KN) | 60 | 60 | |

| Vibration Frequency (HZ) | 0-50 | 0-50 | |

| Power(KW) | 40.58 | 33.58 | |

| Molding Method | Automatic charging, vibrating and pressing | Automatic charging, vibrating and pressing | |

| Control Mode | Full automatic PLC control | Full automatic PLC control | |

| Molding Cycle(S) | 15-20 | 15-20 | |

| Frame Dimension(mm) | 8740×2000×2800 | 7160×2000×2800 | |

| Net Weight of Host Machine(T) | 8.2 | 7 | |

| Bamboo Pallet | 880×680×20 | 880×680×20 | |

| Annual Output based on double shift of 300 days | block(m³) | 85,000 | 85,000 |

| paving stone(㎡) | 362,000 | ------ | |