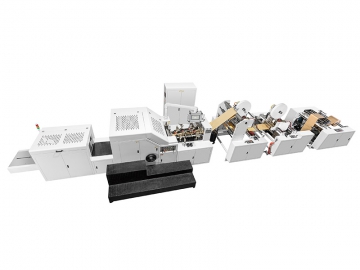

Block Making Machine, Q(F)T10-15

Descriptions

The Q(F)T10-15 block making machine takes prides in producing all sizes of concrete blocks and pavers, with an annual output of 14000m3 blocks and 691,000m3 pavers. It realizes automatic production under PLC control and ensures easy operations.

The automatic concrete block machine or concrete paver machine provides multi language options. The language can be set through the user-friendly human-computer interface. And its easy communication between Man and Machine can realize program management.

Digital Control Panel Characteristics

-- It is a new electrical control and fault diagnostic system:

-- The operator can monitor and control the block making machine through the control panel;

-- Touch screen allows users to set the machine to the desired operating sequence;

-- Pre-vibration times, final vibration time and the number of tamps are changed automatically;

-- If the machine suddenly stops, the screen will display where the fault is and gives description.

Raw Materials

Concrete fed into the block making machine is made from a wide range of raw materials including crushed stone, sand, cement, dust and coal, fly ash, cinder, slag, gangue, gravel, perlite and other industrial wastes

Features

1. It can produce various sizes of pavers by changing moulds.

2. The paver block machine is remarkably eco-friendly and energy saving in that it utilizes some waste materials as raw materials.

3. Automatic charging of materials can enhance the strength and density of finished pavers.

Applications

The block making machine is excellent for construction industry, producing high quality solid, hollow and cellular blocks, paving stones, garden and landscaping products, slabs, curbstones, turf blocks, slope protection blocks, interlocking blocks, etc. for building, road paving, landscaping and other construction projects.

| Type | |||

| Exciting Force (KN) | 100 | 100 | |

| Vibration Frequency (HZ) | 0-60 | 0-60 | |

| Power (KW) | 57.88 | 50.88 | |

| Molding Method | Automatic charging, vibrating and pressing | Automatic charging, vibrating and pressing | |

| Control Mode | Full automatic PLC control | Full automatic PLC control | |

| Molding Cycle (S) | 15-20 | 15-20 | |

| Frame Dimension (mm) | 8700×2500×3020 | 7500×2500×3020 | |

| Net Weight of Main Machine (T) | 12.2 | 11 | |

| Bamboo Pallet | 1220×900×25 | 1220×900×25 | |

| Annual Output based on double shift of 300 days | Block (m³) | 140,000 | 140,000 |

| Paver (m3) | 691,000 | ------- | |