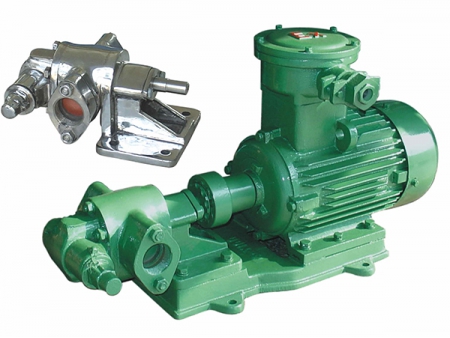

Powdered Metal Gear

Powder metallurgy is ideal technology when it comes to manufacturing gears. Implementing the compacting operation using a mechanical press or hydraulic press, different gears are produced directly from 10mm to 150mm in diameter, such as spur gears, straight bevel gears, double gears, pinion gears and ratchet gears. In order to improve their mechanical strength and hardness, they are finished with a sintering process and heat treatments (case hardening, carbonitriding, high-frequency quenching, steam treatment). The powder metallurgic gears manufactured by imported Hoganas metal powder have the features of high strength and density. We also have machining centers for secondary finishing processes and to meet various precision requirements. Compared to steel gears, the PM gears have advantages of energy savings, costs and higher production efficiency, and lower noise level.

Custom RangeSize range: outer diameter ∅8-∅120 mm;

Precision: grade 7;

Material: iron base alloy (Fe, Cu, C); stainless steel 304L;

Gears for various transmissions.

Driving pinions, sun and planet gears of starter.

Pinions of household appliances.

Gears used to change the speed of high-pressure water sprayers.

Oil pump gears.

Fuel pump gears.

Water pump gears.

(Timing belt pulley, Camshaft pulley, Crankshaft pulley)

(Internal ring gears, Internal gear pairs, Eccentric gears, Ratchets,etc)

Gears and toothed parts are applicable for many purposes.