Plasterboard Plant

Request a Quote

Plasterboard features lightweight, fireproof, heat and noise isolation, is widely applied in architectural engineering, suitable for dry construction, performs a good convenience and quality in engineering. LVJOE is dedicated to developing and manufacturing plasterboard plant since 1998, offers qualified products and professional experienced service to customers from all over the world. Services we offer include:

- Customized complete plasterboard plant, production power from 2 million m2/year to 50 million m2/year. Also offers various devices according to your needs;

- Improve or exchange customer’s devices with problem according to customer’s requirement;

- Consulting and technical improving service on your existing plants, to improve production quality and save cost;

- We offer a complete plasterboard plant production management and maintenance service if you lack operation and management personnel, to achieve better economic benefit for you;

- Plasterboard factory designing and planing service;

- We can offer you the best formula by analyzing the materials you use to produce plasterboard, to ensure quality of the products.

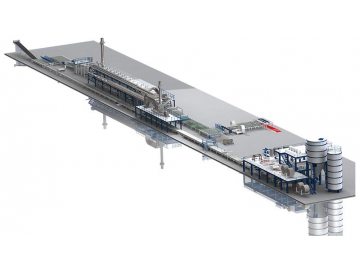

Our plasterboard plant consists of multiple units responsible for several processes, controlled by integrated controlling system. Units including:

Features:

- Unique impeller feeder and accurate electronic belt weigh ensures the reliability of gypsum powder feeding;

- PLC system featuring centralized control and data sharing, able for monitoring and adjusting every procedure on production line, to ensure normal running.

- Drying system applies horizontal-vertical hot air circulation structure to ensure plasterboards are heated evenly.

- Self developed new-type mixer, which is able to prevent slurry from caking, an is energy-saving.

Regular sizes of plasterboard plant produced plasterboard:

Length: 1.2m-4m

Width: 1.2-1.4m

Thickness: 7mm-12mm

(Customizable)

Drywall plant, Consumption of Raw Material (Take 9.5mm thickness board for example)

| Raw Material Designation | Consumption(kg/㎡) |

| Gypsum powder | 5.7-6.1 |

| Faced Paper 210/㎡ | 0.42 |

| Water | 4.3-4.9 |

| Modified Starch | 0.25-0.30 |

| Foaming Agency | 0.008-0.011 |

| Emulsion (White Latex) | 0.006-0.007 |

| Electricity | 0.3-0.4 kwh |

| Coal | 0.7-1.0 kg(6000 Kcal) |

Get in touch with us