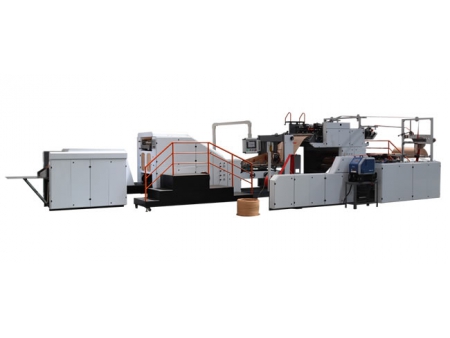

Block Making Machine, QT4-25

Description

--Our QT4-15 block making machine is widely used to produce all sizes of concrete blocks as customers' requirements.

--State of the art PLC control system ensures ease of operation.

--Multi language options set through the user-friendly Man-Machine interface enable the building material machinery to be used in various countries.

--Easy communication between operator and the construction machine makes it possible to realize program management.

--Many models of brick machines are available here for you to choose according to practical need.

Raw Materials

Crushed stone, sand, cement, dust and coal, fly ash, cinder, slag, gangue, gravel, perlite and other industrial wastes

Features

1. Only by changing of moulds can this block making machine produce blocks in a diversity of sizes.

2. It uses some waste materials to make blocks, thus saving energy and ensuring outstanding environmental performance.

3. The concrete brick making machine features automatic material feeding. That can highly increase the strength and density of finished blocks.

Applications

Our QT4-15 block making machine is widely used to make various types of concrete blocks including Solid, hollow and cellular blocks, paving stones, garden and landscaping products, slabs, curbstones, grass blocks, slope blocks, interlocking blocks, etc. It is widely applied in a number of fields such as building, road construction, landscaping, and others.

| Type | ||

| Exciting Force (KN) | 50 | |

| Vibration Frequency (HZ) | 0-50 | |

| Power(KW) | 10.7 | |

| Molding Method | Semi-auto charging, vibrating and pressing | |

| Control Mode | Manual or Auto | |

| Molding Cycle(S) | 20-25 | |

| Frame Dimension(mm) | 4388×1660×2100 | |

| Net Weight of Host Machine(T) | 3 | |

| Bamboo Pallet (mm) | 840×500×20 | |

| Annual Output based on double shift of 300 days | Block(m³) | 30,000 |

| Paving stone( ㎡ ) | ----- | |