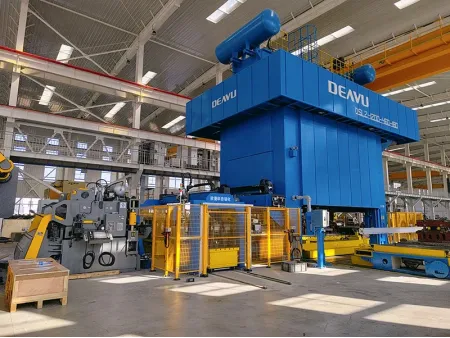

Eccentric Geared Link Motion Mechanical Press

DS2/DSL2 Stamping Presses

- Capacity 400T to 1250T

- Strokes per minute 8SPM to 25SPM

- Stroke length 500mm to 800mm

- Slide area 2800×1600mm to 4000×2000mm

The DS2/DSL2 eccentric geared link motion mechanical press features a high-rigidity welded steel frame with top beam, columns, and base connected by four pre-tensioned reinforcement rods, delivering excellent stability and precision for demanding metal stamping, punching, bending, cutting, and blanking operations. This press is designed to handle a variety of production conditions, making it ideal for hardware manufacturing, automotive parts, and precision applications.

With a capacity from 400T to 1,250T and stroke speeds between 8 and 25 SPM, the eccentric geared link motion mechanical press ensures reliable, high-precision performance. Manufactured to Japan’s JIS Grade-1 precision standards, it provides long-term operational stability.

- Hardware: hinges, locks, screws

- Automotive components

- Other products: seat belt buckles, filter housings, surgical clamp joints

- Eccentric gear drive system for stable transmission and low noise

- High-performance hydraulic overload protection with long, four-sided guideways for excellent accuracy and minimal side force

- Automatic circulation lubrication system with fixed-point, fixed-quantity oil delivery and detection for pipeline faults or oil shortages

- Expandable for automated feeding systems and high-speed die change systems

| Model | Unit | | | | | |

| Type | S | S | S | S | S | |

| Capacity | T | 400 | 630 | 800 | 1000 | 1250 |

| Rated tonnage point | mm | 13 | 13 | 13 | 13 | 13 |

| Strokes per minute | S.P.M | 8-18 | 8-18 | 10-25 | 8-18 | 8-18 |

| Stroke length | mm | 500 | 600 | 600 | 700 | 800 |

| Max. shut height | mm | 1200 | 1300 | 1400 | 1400 | 1400 |

| Die height adjustment | mm | 500 | 550 | 600 | 650 | 650 |

| Slide area | mm | 2800×1600 | 3200×1800 | 3600×1800 | 4000×1800 | 4000×2000 |

| Bolster area | mm | 2800×1600 | 3200×1800 | 3600×1800 | 4000×1800 | 4000×2000 |

| Air pressure required | kg/cm² | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 |

| Main motor | kW.p | 55 | 75 | 90 | 110 | 132 |

| Opening in side frames | mm | 1600 | 1800 | 1800 | 1800 | 2000 |

| Slide adjustment mechanism | Electric | |||||

| Die cushion | 1 pad, 2 cylinder | |||||

| Die cushion capacity | ton | 80 | 100 | 150 | 150 | 200 |

| Die cushion stroke length | mm | 200 | 200 | 250 | 250 | 250 |

| Max. upper-die weight | ton | 10 | 12 | 15 | 18 | 20 |

| Model | Unit | | | | |

| Type | S | S | S | S | |

| Capacity | T | 630 | 800 | 1000 | 1250 |

| Rated tonnage point | mm | 13 | 13 | 13 | 13 |

| Strokes per minute | S.p.m | 8-18 | 8-18 | 8-18 | 8-18 |

| Stroke length | mm | 800 | 1000 | 1100 | 1200 |

| Max. shut height | mm | 1200 | 1300 | 1400 | 1500 |

| Die height adjustment | mm | 500 | 550 | 600 | 700 |

| Slide area | mm | 3600×1800 | 3800×1800 | 4000×2000 | 4000×2200 |

| Bolster area | mm | 3600×1800 | 3800×1800 | 4000×2000 | 4000×2200 |

| Air pressure required | kg/cm² | 0.55 | 0.55 | 0.55 | 0.55 |

| Main motor | kW.p | 110 | 132 | 160 | 220 |

| Opening in side frames | mm | 1800 | 1800 | 2000 | 2200 |

| Slide adjustment mechanism | Electric | ||||

| Die cushion | 1 pad, 2 cylinder | ||||

| Die cushion capacity | ton | 150 | 200 | 250 (with optional lock) | 250 (with optional lock) |

| Die cushion stroke length | mm | 250 | 250 | 300 | 300 |

| Max. upper-die weight | ton | 12 | 15 | 18 | 20 |

- Variable speed drive

- Hydraulic overload protector

- Die area light

- Electrical slide adjustment

- Photoelectric safety device

- Digital die height indicator

- Slide and die counterbalance system

- Electronic encoder

- Misfeed detector

- Power socket

- Human-machine control system (Defu)

- Overrun safety device

- Air ejector

- Maintenance tool box

- Operating manual

- Wet clutch

- Pneumatic die cushion

- Foot switch

- Quick die change

- Slide knockout

- Automatic uncoiler

- Intelligent manipulator

- Moving bolster

- Slug detector (Riken Optech Corporation)

- Tonnage monitor

- Front safety door

- Back safety door

- Safety die block with plug

- Separate clutch and brake

- Flywheel brake

Designs are subject to change without prior notice and can be customized according to your requirements.

Our product brochure

The eccentric geared link motion mechanical press provides stable, precise, and efficient performance for high-demand stamping operations. Contact us to learn more and find the right solution for your production needs.