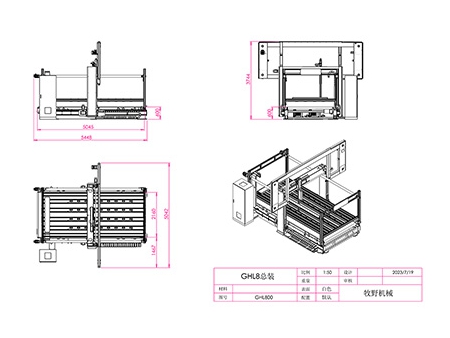

Foam Cutter (Horizontal CNC Contour Cutting Machine, Model GHL8)

Usage

The horizontal foam cutter can cleanly cut nearly any desired geometric profile, which can then be used in a number of industries.

Materials suitable for cutting

Polyurethane, HR CMHR, PU flexible foam, sticky foam, latex, Basotect, rebond foam, frame foam, polyethylene.

Shapes

This particular machine is ideal for cutting blocks, 2D and 3D products, and wavy, curved, regular and irregular shapes.

| Standard | Option | |

| Length of the foam block | 3000mm | 4500mm/5000mm |

| Height of the foam block | 1250mm | 1500mm |

| Width of the foam block | 2200mm | 2300mm |

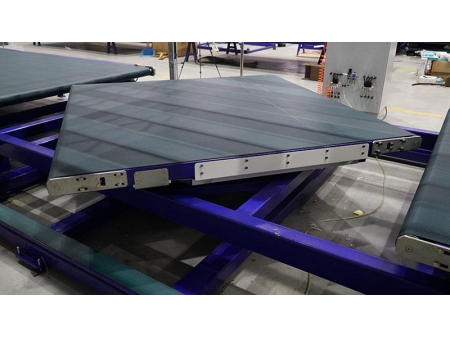

| Work table | Conveyor belt worktable | |

| AC power | 380V 3 phase 4 wire | |

| Total power | 30kW | |

| Max. feeding speed | 40m/min | |

| Cutting precision | ±1mm | |

| Cutting tool | Air pressure: 6 bar Continuous blade Blade size: 13090mm×3.2mm×0.6mm Line speed: 15m/s | |

| Standard configuration | Remote diagnosis and maintenance Automatic programming software Absolute value control Automatic angle adjustment Manual angle adjustment Automatic loading monitoring Automatic press device Vacuum suction system (for foam holding) | |

| Optional configuration | Automatic sharpening system Loading conveyor L3300mm Unloading conveyor L3300mm | |

| Max cutting speed | Different cutting materials will be cut at different speed. And the max. speed is 30 meters/minute. | |

Based on the original GH1 horizontal foam cutting machine, the GHL8 foam cutter jumps ahead of its time. Users who need to cut large quantities of foam into irregular shapes will find this machine ideal. As production requires, the contour cutting line can cut foam placed on the worktable either as a whole or in small steps, and this CNC foam cutter has an automatic continuous operation.

Features

1. This machine covers a small floor area (only 5% of that taken up by a similar machine)

2. It has low power consumption.

3. The cutting machine also has a high cutting efficiency. (The contour cutting line uses an endless knife rather than an oscillating knife, making the cutting speed 2 or 3 times faster than the original speed.)

4. This CNC contour cutting line features a high cutting precision, utilizing a unique design on its rotary platform with a pressure rack.

5. It is convenient for packaging, as processing and packaging can occur simultaneously.

6. The GHL4 machine uses as much foam as possible in an effort to reduce waste.

7. It significantly reduces manual labor and production costs.