Adjustable Stroke Press (Nominal force: 250kN~2500kN)

Request a Quote

Description

The JL21 series adjustable stroke press is a new generation of general sheet fabrication equipment developed at the basis of Japanese AIDA advanced technology. It is suitable for shearing, punching, blanking, bending and shallow drawing jobs.

The metal stamping press is configured with two-hand operation buttons and foot switch etc., which can realize continuous, single and micro-inching operating specification.

Parameters| Type | JL21-25 | JL21-45 | JL21-63 | JL21-80 | JL21-110 | JL21-125 | JL21-160 | JL21-200 | JL21-250 | ||

| Nominal force | kN | 250 | 450 | 630 | 800 | 1100 | 1250 | 1600 | 2000 | 2500 | |

| Nominal stroke | mm | 3 | 4 | 4 | 5 | 6 | 6 | 6 | 6 | 8 | |

| Slide stroke | mm | 10-110 | 20-120 | 10-150 | 10-150 | 10-160 | 10-160 | 16-160 | 19-180 | 21-220 | |

| Number of strokes | Fixed | Times/min | 100 | 80 | 70 | 60 | 50 | 50 | 40 | 35 | 30 |

| Variable (Optional) | 80-120 | 70-90 | 60-80 | 50-70 | 40-60 | 40-60 | 35-50 | 30-40 | 25-35 | ||

| Max. die height | mm | 250 | 270 | 300 | 320 | 350 | 350 | 350 | 450 | 500 | |

| Die height adjustment | mm | 50 | 60 | 80 | 80 | 80 | 80 | 110 | 110 | 120 | |

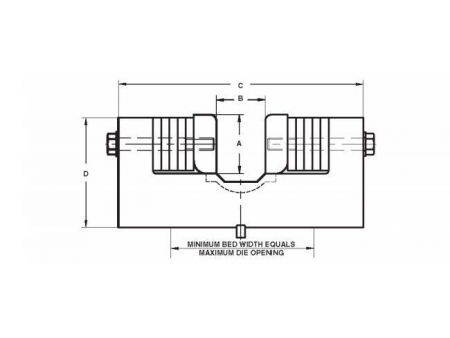

| Distance between slide center and frame (Throat depth) | mm | 210 | 230 | 300 | 300 | 350 | 350 | 380 | 390 | 420 | |

| Column spacing | mm | 450 | 550 | 620 | 640 | 710 | 760 | 810 | 870 | 960 | |

| Bolster area (F.B × L.R) | mm | 400×700 | 440×810 | 580×900 | 580×1000 | 680×1150 | 680×1150 | 740×1300 | 760×1400 | 800×1400 | |

| Bolster thickness | mm | 80 | 110 | 110 | 120 | 140 | 140 | 150 | 160 | 170 | |

| Bolster opening (Upper hole dia. × Depth × Lower hole dia.) | mm | φ170×20×φ150 | φ180×30×φ160 | φ200×40×φ180 | φ200×40×φ180 | φ260×50×φ220 | φ260×50×φ220 | φ300×50×φ260 | φ300×50×φ260 | φ320×50×φ280 | |

| Slide area (F.B × L.R) | mm | 300×360 | 360×600 | 400×680 | 440×710 | 500×810 | 500×810 | 580×920 | 600×920 | 650×970 | |

| Shank hole (Dia.× Depth) | mm | φ40×60 | φ40×60 | φ50×80 | φ50×80 | φ60×80 | φ60×80 | φ65×90 | φ65×90 | φ70×90 | |

| Main motor power | kW | 4 | 5.5 | 7.5 | 7.5 | 11 | 11 | 15 | 18.5 | 22 | |

| Outline dimension (F.B×L.R×H) | mm | 1500×950×2650 | 1610×1170×2850 | 1680×1260×3050 | 1750×1310×3150 | 1850×1400×3250 | 1850×1450×3250 | 2250×1560×3765 | 2500×1580×3420 | 2730×1640×3550 | |

| Net weight | kg | 3100 | 4350 | 6500 | 8500 | 10000 | 10700 | 14500 | 17950 | 25400 | |

| | | | | | | | | | |||

- High-rigidity steel-plate welded frame.

- Combined dry pneumatic friction clutch

- Cylinder type stroke adjusting structure

- The slide is guided by eight-sided guide, among them, JL21-25 hydraulic presses by six-sided guide.

- Hydraulic overload protection device

- Automatic oil circulating lubricating system. JL21-25 employs electric grease lubrication.

- JL21-63, JL21-80, JL21-110, JL21-125, JL21-160, JL21-200, JL21-250 series stamping presses adopt electric die height adjustment with digital display.

- Lifting counterbalance cylinder

- Dual solenoid valve

- Integrated control panel (electronic cam included)

- International brand PLC control

- International brand buttons, AC contactor, air switch

- Option: Air cushion (airbag type or cylinder type), automatic feeding shaft, photoelectric protective device, slide knockout device, and can be matched with all kinds of automation equipment.

- Drive gears enclosed inside the press frame, gears immersed in oil for lubrication

- The slide is a cast box structure fitted with hydraulic overload protector acting sensitively and reliably. After overloaded it can automatically reset that can reduce downtime as well as improve the working efficiency of the press machine.

- Employ eight-sided rectangular lengthened guide with high guide precision and good precision retaining ability.

- Adopting Omron programmable controller (PLC) for centralized control that can effectively guarantee the reliability of the electric control parts.

- Japanese TACO duplex safety valve is employed to ensure the safety and reliability of clutch operation.

- Cam controller made up of Schneider switches can send out signal accurately within 360°, precisely control all action specifications of main machine as well as coordination with accessory machine, so as to improve the running reliability of the press.

Related products

Send Message

Most Recent

More

Other Products

Videos