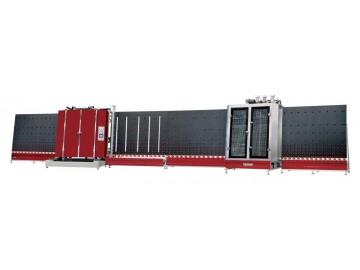

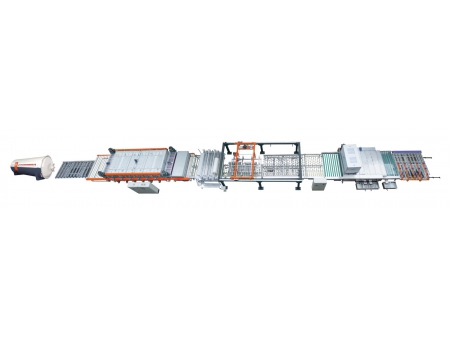

GPL-XY1800-NW Insulated Glass Production Line

Request a Quote

This GPL-XY1800-NW insulated glass production line has the functions of interior pressing and exterior pressing, and the whole line is solely controlled by PLC control system and dual touch screen display system, the glass washing machine is equipped with 3 pairs of fur brushes which are specialized for Low emissivity glass. The pressing plates of the coupling press unit can automatically expand and is easy to maintain. It is applicable for manufacturing two-layer insulating glass, three-layer insulating glass, curtain wall insulating glass and special insulating glass.

Parameter

- Input Voltage: 380V 50Hz

- Total Power: 20KW

- Cutting Glass Size: 1800×2500mm

- Min Glass Size: 300×450mm

- Glass Thickness: 4~10mm

- Working Speed: 6~48m/min

- Total Weight: 5500kg

- Size of Line: 18000×2350×2750mm

Feature:

- The pressing plates of the coupling press unit can automatically expand and is easy to maintain.

- The glass washing machine is equipped with 3 pairs of fur brushes which are specialized for Low emissivity glass and will not damage the film layer of glass during the cleaning process.

- It is applicable for manufacturing two-layer insulating glass, three-layer insulating glass, curtain wall insulating glass and special insulating glass.

- This production line is equipped with a buffer storage area which can increase the production efficiency.

- The whole equipment adopts PLC control system, it adopts touch screen as display screen, which can display the temperature and speed of water, production output and so on. And there will be prompt message on the display when equipment errors happen.

- Manipulators are used for glass uploading, which makes sure that the glass is not broken or dislocated.

Maintenance

- Transmission part

- Calcium base grease need to be regularly injected to bearings, chain wheels, gears

- Calcium base grease need to be injected to reducer every half year.

- Check regularly if there is any jackscrew at the bottom of washing machine and inside the rubber tire of washing cabinet loosening. If there is, you should fasten it in time.

- Washing part

- The recycling water needs to be changed everyday, and the water cabinet needs to be washed weekly; Check the water spray nozzle and clear up it if there is blocking.

- Pressing part

- Check the electric equipment before using to make sure the normal operation of pressing machine.

- Routine cleaning for the front plate and back plate of washing machine to guarantee there is no pollution for the washed glass.

- It is absolutely forbidden to put hands between front plate and back plate before the power supply shut off.

- Touch screen is only allowed to be touched when changing the operating mode and setting parameters, too much touching strength is not allowed to prevent the touch screen from damaging.

- Change lubricating oil for rolling transmission reducer after using for first 400h, and later change lubricating oil every 4000h.

- Clean air should be dry, and the water in air filter needs to be discharged regularly.

- Check the oil regularly for air lubricator and replenish the 2.5º-7ºE oil in time.

- The filtrating screen of aeromix needs to be cleaned often.

- The lifting machine and lifting glass before and after pressing machine are sure to be higher 5mm than transmission wheel, or there will be faulted segment or glass cullet.

Recommended matched equipment

Related products

Send Message

Most Recent

More

Other Products

Videos