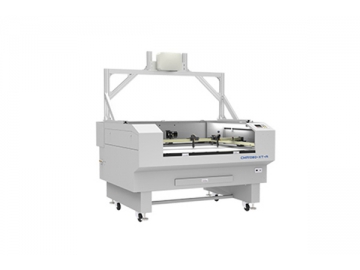

1550×1000mm Projector Positioning Double Head CO2 Laser Cutting Machine, CMA1610-XT-A

Applicable Materials

The CMA1610-XT-A laser cutter is applicable for materials like cloth, woven sneakers, lace, cotton and linen, mesh and so on.

Cutting System

| Model | Laser power (W) | Laser head | Working area (mm) | Overall dimension (mm) | Weight (Kg) | Repeated positioning accuracy (mm) | Speed (m/min) | Supply voltage | Working environment |

| CMA1610-XT-A | 60~130 | Double | 1550×1000 | 2200×1690×1170 | 420 | ±0.1 | 0~30 | 220~240V, 50/60Hz | Temp: 5~40°C , Humidity: 5~80%. No condensate water, no dust or less dust. |

Laser Processing Examples:

- Garment laser cutting and hollowing

- Laser cutting of bras

- Laser cutting of bras

- Laser cutting of hair clip

- Laser cutting of lace

- Leather laser cutting

- T-shirt laser cutting

Product Feature

1. The projector support uses an aluminum profile or sheet metal bending parts, which provides various assembly options in order to satisfy onsite modification.

2. An compact structure, high space utilization rate and double head linkage significantly improve the working efficiency.

3. The system is equipped with our self-developed SmartCarve software and motion controller, which ensures high speed and stable machine operation.

4. The use of a high-quality projector with ultra-high brightness and contrast ratio ensures clearer lines.

5. This system supports cutting recovery after power off and a preview of the working time. It also supports the dynamic display of process path and coordinate points, as well as real time display and tracking.