Automatic Can Seamer

Request a Quote

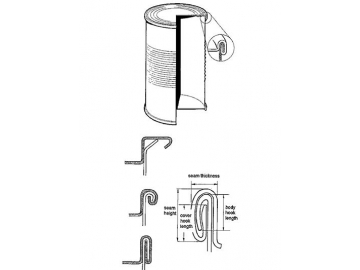

Automatic can seamers are used for can sealers, and work in conjunction with can filling machines. STWMF’s can seamers are suitable for a variety of can types, just by changing the dies used.

STWMF provides different automatic can seamer types as shown here:| Machine type | Application | Speed level | Max. capacity |

| ST-B15 | Food cans | Medium | 400CPM |

| ST-B15APH | Aerosol spray cans | Medium | 180CPM |

| ST-B6CL | Large cans | Medium | 220CPM |

| ST-B15A | Food cans | Medium | 450CPM |

| ST-B83A | Food cans | High | 500CPM |

| ST-B83AS | Small food cans | High | 500CPM |

| ST-C3AL | Food cans, chemical cans | Low | 65CPM |

- Protection design for vacant can feeding. If there are no cans entering the seaming machine, the end feeding system will immediately stop, then resume when cans enter.

- Automatic oil lubricating system for driving parts, which reduces abrasion and improves the service life.

- Stepless variable-speed pulley (speed ratio of 1:3)

- Steam deoxygenation equipment can be installed. Removing oxygen from cans via steam prevents food deterioration.

- Jet printers can be installed for packaging

- Matching with different can filling machine types can be carried out with an adjustment to the installation position and machine speed.

- Cans rotating for seaming with seamer head fixed. Simultaneous multiple can seaming improves efficiency and floor space utilization

- Timing screws are installed at can bases, which can reduce can shaking and avoid material leakage during the seaming process.

- Frequency inverters for convenient speed adjusting

- Non-contact, no can, no cap feeding device and automatic stopping device for insufficient caps.

- Hard chromium plating on the interfaces with cans, thus avoiding abrasion

- Stopping devices ensure machine and operator safety.