Vacuum Paddle Dryer

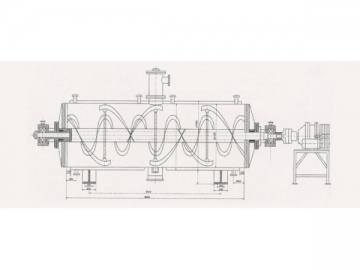

The ZHG vacuum paddle dryer is a horizontal batch dryer manufactured using advanced paddle drying technology. Moisture in the raw materials is evaporated while the material is conveyed through the machine. A mixer with a scraper blade continually removes materials from the hot surface and circulates them in the paddle dryer's chamber. Vapor is exhausted through a vacuum pump.

As a leading paddle dryer manufacturer in China, we've created a vacuum paddle dryer that is more than 10m3, currently the largest in the industry. Our vacuum paddle dryers use various sealing methods and material and have an option of six types of mixing mechanisms. Depending on the material being processed, our vacuum drying machine can be designed to ensure strength, concentricity, effective heat transfer area and long service life.

Features of the ZHG Vacuum Paddle Dryer

1. Having a large-scale jacketed heating area, its heat conducting area and heat efficiency are high.

2. A paddle in the machine continually stirs raw material inside the body for uniform heating.

3. The paddle in the vacuum dryer easily dries slurry and paste material.

4. A specially designed outlet allows for better sealing and less accumulation of the product. Dispensing is easy. (The design has been applied for patents.)

5. Two sealing models-mechanical sealing and packing sealing-are effective and long lasting.

6. The specially designed shaft and rake provide good strength and concentricity of the end product.

7. The material for the shaft and vibration depends on the customer and application requirements.

8. Different filters are available according to preferred material.

9. A half-pipe jacket is used when the volume of the vacuum paddle dryer is more than 5m3.

Technical Parameters of the ZHG Vacuum Paddle Dryer

| Item | Name | Working Volume | Size of inner chamber | Agitating speed | Power | Pressure in chamber |

| Unit | L | mm | rpm | kw | Mpa | |

| Model | 300 | Ø600*1500 | 5-25 | 4 | -0.186 | |

| 450 | Ø800*1500 | 5-12 | 5.5 | |||

| 600 | Ø850*1800 | 5 | 5.5 | |||

| 900 | Ø1000*2000 | 7.5 | ||||

| 1200 | Ø1200*2000 | 11 | ||||

| 1800 | Ø1200*2600 | 15 | ||||

| 2400 | Ø1400*2600 | 18.5 | ||||

| 3000 | Ø1500*3000 | 22 | ||||

| 4200 | Ø1600*3600 | 30 |