Right Angle Speed Reducer

The ZR series of speed reducers feature input and output components at 90 degree angles for small and compact mounting as well as efficient transmission. These gearboxes are primarily used in automation machinery.

These right angle speed reducers are used for automation machinery in applications such as printing, bending, spring machinery, LCD inspection equipment, and a transmission mechanism.

| Model No. | Unit | Ratio | ZR42 | ZR42S | ZR60 | ZR60S | ZR90 | ZR90S | ZR120 | ZR120S |

| Rated Output Torque | Nm | 2 | / | / | 45 | / | 120 | / | 160 | / |

| 3 | 15 | / | / | / | / | / | / | / | ||

| 6 | / | / | / | 45 | 320 | / | 450 | |||

| 8 | / | / | / | 45 | / | 320 | / | 450 | ||

| 9 | / | 15 | / | / | / | / | / | / | ||

| 10 | / | / | / | 45 | / | 320 | / | 450 | ||

| 12 | / | 15 | / | / | / | / | / | / | ||

| 14 | / | / | / | 45 | / | 320 | / | 450 | ||

| 15 | / | 15 | / | / | / | / | / | / | ||

| 20 | / | / | / | 45 | / | 320 | / | 450 | ||

| 21 | / | 15 | / | / | / | / | / | / | ||

| 30 | / | 15 | / | / | / | / | / | / | ||

| Max. Output Torque | Nm | 2 | / | / | 120 | / | / | / | / | / |

| 3 | 40 | / | / | / | / | / | / | / | ||

| 6 | / | / | / | 120 | / | 320 | / | 450 | ||

| 8 | / | / | / | 120 | / | 320 | 450 | |||

| 9 | / | 40 | / | / | / | / | / | / | ||

| 10 | / | / | / | 120 | / | 320 | / | 450 | ||

| 12 | / | 40 | / | / | / | / | / | / | ||

| 14 | / | / | / | 120 | / | 320 | / | 450 | ||

| 15 | / | 40 | / | / | / | / | / | / | ||

| 20 | / | / | / | 120 | / | 320 | / | 450 | ||

| 21 | / | 40 | / | / | / | / | / | |||

| 30 | / | 40 | / | / | / | / | / | / | ||

| Rated Input Speed | Rpm | 2-30 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| Backlash | Min-arc | 2-30 | 0.5 | 2 | 0.5 | 2 | 0.5 | 2 | 0.5 | 2 |

| Weight | Kg | 2-30 | 0.5 | 0.9 | 1.2 | 2 | 3.6 | 6.5 | 8 | 15.5 |

| Servo Motor Power | W | 2-30 | 100 (AC) | 100 (AC) | 200~400 (AC) | 200~400 (AC) | 750 (AC) | 700 (AC) | 1100-1500(AC) | 200~400 (AC) |

| Stepper Motor Type | 2-30 | 42 | 42 | 60 | 60 | 86 | 86 | 80 | 60 |

1. Low rotating backlash is less than 10 Sec.

The right angle reducer is processed using a high precision six axial machine. It is clamped and finished all in one process.

The transmission is precise, quiet, stable and smooth for high quality equipment operation.

2. The gearbox is compact and yet highly efficient.

3. High output torque and low backlash despite its small volume and light weight.

4. Consider the flange and shaft size of your motor prior to placing your order.

1. Mounting dimensions: input and output dimensions must be identical for the right angle gearbox to operate properly.

2. Ratio: Rated output speed of motor/gear ratio=Output speed of gearbox. Selecting the closest desired ratio is the best way to realize the desired speed.

3. Torque: The rated output torque of the gearbox must be greater than the connected servo motor’s output torque (stepper motor: holding torque)*ratio. If it is less than this value, the service time is shortened and the gears and shaft will become damaged.

4. Backlash: One round is 360 degrees and 1 degree= 60 arc-min. These gearboxes feature minimal backlash and maximum precision. Radial stress and average working lifetime should be considered. Gearboxes with heavy radial stress have a higher reliability. The average working life of the gearbox is considerably greater than the servo motor.

These gearboxes feature patented technology that significantly enhance transmission performance.

Patent 1: Reduce the axial thrust caused by the running of planet gears.

Patent 2: Enhanced lubrication for reduced frictional resistance and noise.

1. Gear box: Constructed from high strength alloy steel, the gear box features high precision and high output torque. It is also corrosion resistant.

2. Output shaft: The integrated structure and nickel electroless treatment ensures rigidity under maximum output torque.

3. Sun gear and planet gear: The sun gear’s surface is carburized to supply high anti-wearing and impact resistance. Truing gears enhance their precision and reduce noise. Crowded needle rollers are used in the inner hole of the planet gear.

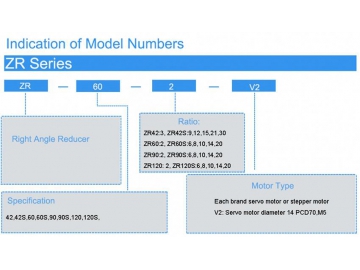

ZR-42 series--each brand 100W AC servo motor, each brand model 42 stepper motor

ZR-60 series-- each brand 200-400W AC servo motor, each brand model 60 stepper motor

ZR-90 series--each brand 750W AC servo motor, each brand model 86 stepper motor

ZK-120 series--each brand 1.1-1.5KW AC servo motor, each brand model 86 stepper motor

Installation

1. Coat the motor output shaft and flange with anti-rust oil.

2. If using a bushing on the gearbox input shaft, align the bush groove with the gearbox input shaft groove.

3. Put the motor on a flat surface with its axle upward. Then fix the motor and remove the key.

4. Set screws onto the input end and lock it into place.

5. Fasten the screws between the motor and gearbox.

6. Fasten the fixed screws on the side of the gearbox.

Lubrication:

1. The gearbox is securely sealed and the oil does not require replacement.

2. The oil is a semisolid high-grade synthetic lubricant.

3. Operation temperature: 0-+40 degrees

4. The highest allowable temperature of the gearbox body must remain below 85 degrees to prevent failure.

Note: If the temperature of the working conditions is below 0 degrees, please specify prior to ordering.

Quality guarantee of gearbox:

Under normal usage, warranty of the gearbox is 1 year from the date of delivery.

Under normal usage, warranty for anti-leaking is 2 years.

Note: Human error or natural disasters are not covered under warranty.

How to store the reducer?

1) Keep the reducer in a clean, dry place.

2) If it will be stored outdoors or in a humid place, please put the reducer in a box packed tightly with a plastic bag to avoid rain exposure and external erosion.