UV Offset Varnish

Introduction

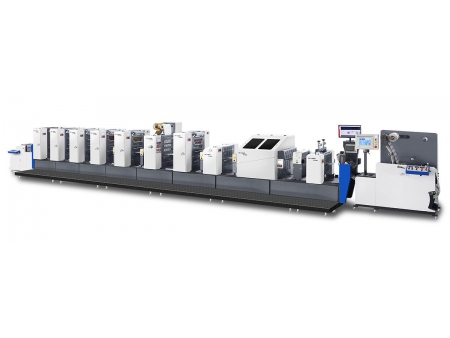

Our UV offset varnish, generally used alone or being mixed for glossing, is widely used for varnishing gold and silver paperboard and various kinds of papers. This gloss oil now owns two new models i.e. UVJ-1# and UVJ-3# that are specially developed by improving the ordinary UV varnish which may generate water spray and conglutination phenomena when the thermal contraction film is heat sealed.

KAISHIMEI UV high gloss varnish comes with no water-spray, no conglutination and non-yellowing but with good glossiness. It is specifically applicable to the post-offset varnishing for cigarette packaging, wine packaging and toothpaste box.

Product Specifications of UV Offset Varnish| Product Model | |

| Appearance | Transparent primrose liquid |

| Specific gravity | 1.05g/ml |

| Viscosity (25℃) | 70 -150cps |

| Nonvolatile elements | Above 99% |

| Substrates | gold & silver paperboard |

| Drying speed (three 80W/cm UV lamps) | ≤3 seconds |

| Typical feature | water-spray resistance |

Advisable Use Methods

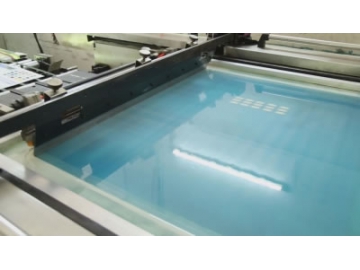

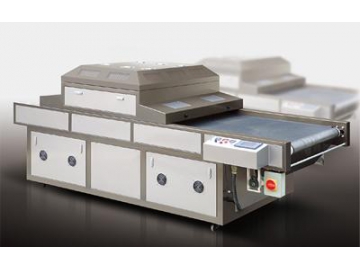

1. Varnishing process: Firstly, this varnish can be painted on the paperboard, and then you can cure it by UV rays.

2. Oiling capacity depends on the requirement of paper brightness, generally covering 4-6g/cm2. Excessive coating or uneven oiling will reduce the brightness.

3. After oiling, UV lamps should be opened in full power to dry the oil paint. Otherwise, the finished surface can hardly resist abrading and scratching.

4. KAISHIMEI offers special cleaning agent to clean roll coater.

Notice

1. Please use soap to clean immediately if our UV offset varnish is spattered on your skin.

2. Store this varnish for offset printing in cool and shady place. Storage period is six months.

3. Avoid being exposed under strong light for a long time.

4. IPA can be taken as machine cleaning agent

Packaging

Elegant plastic drum packaging, with net weight of 30 kilograms.