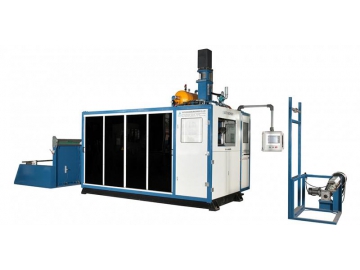

DW3 3-Station High Speed Thermoforming Machine

Description

DW3-78 high speed thermoforming machine with maximum forming area of 800mm×600mm and is equipped with three stations, which are respectively responsible for forming, cutting and stacking suitable for PP, PS, OPS, PET, PVC, PE, PLA and other materials.

The machine is mainly applied to manufacture plastic products such as plastic bowls, plastic plate, food containers, plastic trays and so on, which is widely applied to food package, electronics packaging, medical packaging, automobile packaging, etc.

Sushi box

Sushi box Food container

Food container

Technical progress

| Maximum forming area | 800×600 | mm |

| Minimum forming area | 375×270 | mm |

| Maximum tool size | 780×560 | mm |

| Suitable sheet thickness | 0.1-2.5 | mm |

| Forming depth | ≤±150 | mm |

| Work efficiency | ≤50 | pcs/min |

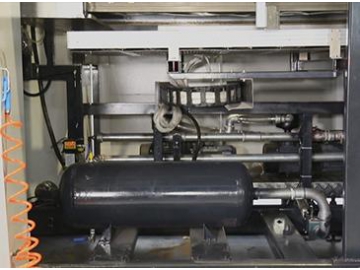

| Maximum air consumption | 5000-6000 | L/min |

| Heating power | 100 | kW |

| Dimension of machine | 13.8L×2.45W×3.05H | m |

| Total weight | 14 | T |

| Rated power | 135 | kW |

Features of DW series high speed thermoforming machine

1. The DW series high speed thermoforming machine has high manufacturing, which can be up to 50 cycles per minute at most.

2. Due to advanced automatic system, absolute value servo control system and operation interface of number axis aided parameter display for controlling, the series of thermoforming machine shows superior performance for processing PP, PS, OPS, PE, PVC, APET, CPET, etc.

3. According to ergonomic principle, we design a simple mould replacing system, which can shorten the mould replacing time.

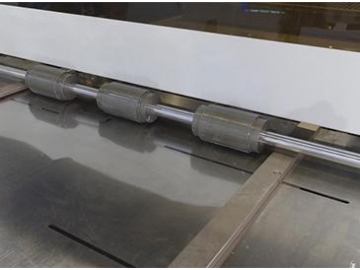

4. The cooperation between cutting type of steel blade and design of stacking equipment can improve manufacturing speed and ensure maximum production area.

5. Advanced heating system adopts new temperature control module with short response time can increase efficiency and reduce energy consumption.

6. The series of DW thermoforming machine has low noise at working and has high reliability, which is very convenient for maintenance and operation.