Hammerhead Tower Crane, QTZ63 TC5010-5

QTZ63 TC5010-5 hammerhead tower crane consists of a horizontal arm, a jib, a hoisting mechanism, a trolleying mechanism, a slewing mechanism, a hydraulic jacking system, a cabin and safety devices. As a city tower crane, it is widely used for constructions of high-rise restaurants, civilian buildings and industrial buildings. It is an ideal choice for small and middle-size construction enterprises.

QTZ63 TC5010-5 hammerhead tower crane consists of a horizontal arm, a jib, a hoisting mechanism, a trolleying mechanism, a slewing mechanism, a hydraulic jacking system, a cabin and safety devices. As a city tower crane, it is widely used for constructions of high-rise restaurants, civilian buildings and industrial buildings. It is an ideal choice for small and middle-size construction enterprises.

Our hammerhead tower crane has many advantages. First, the jib, held by rigid duplex pull rods, features good rigidity, light weight, small cross section, small wind resistance, uniform force distribution and good-looking appearance. The maximum hook radius reaches 48 meters, which makes the crane suitable for many engineering projects. Further, the hoisting mechanism can ensure low-speed heavy loading and high-speed light loading with the help of a three-speed motor and a single-stage gear reducer. The maximum hoisting speed reaches 65 m/min. Thirdly, the operator's cabin runs along the horizontal arm with traction by the trolleying mechanism, which facilitates perfect positioning. The cabin is installed separately at one side of the tower to ensure full view, which provides the operator with a comfortable and convenient working environment. Equipped with a planetary reducer and a hydraulic coupler, the slewing mechanism achieves great bearing capacity, smooth startup, reliable performance, wind resistance and accurate positioning. Further, both single and double slewing mechanisms are all available to meet customers' diversified demands.

Moreover, the hammerhead tower crane can automatically lift itself by adding mask sections using a hydraulic cylinder. Hence, the crane can rise with a building's ascending. In addition, it can be fixed on a base or attached to an external wall. This slewing tower crane is extensively applied for different construction projects. Its freestanding height is 34 meters, while its attached height can be 140 meters and 70 meters respectively for situations with multiplier as 2 and 4.

In general, its performance indexes have come up to top level at home and abroad. It improves the maximum hook radius to 50 meters, which dramatically expands the application scope. The horizontal jib tower crane also features high working speed, excellent speed control performance, stable performance and high efficiency. Automatic manufacture technology we use help to improve production efficiency and reduce production cost at the same time. As a result, our tower crane has remarkable advantages in terms of price compared to similar products on the market.

- Jib

- Mask Section

- Electric Cabinet

- Package

Hammerhead Tower Crane Specifications

Total Power: 29.9kw (single slewing mechanism)/31.8kW (double slewing mechanism)

Voltage: 380V/440V

Frequency: 50Hz/60Hz

| Maximum Hook Radius | m | 50 | 44 | 38 | |||||||

| Rated Load Moment | kN · m | 570 | 600 | 630 | |||||||

| Maximum Hoisting Capacity | T | 5 | |||||||||

| Minimum Hook Radius | m | 3 | |||||||||

| Tip Load | T | a=2 | a=4 | a=2 | a=4 | a=2 | a=4 | ||||

| 1.045 | 1.036 | 1.299 | 1.293 | 1.633 | 1.631 | ||||||

| Radius at Maximum Hoisting Capacity | m | a=2 | a=4 | a=2 | a=4 | a=2 | a=4 | ||||

| 24.17 | 12.92 | 25.23 | 13.48 | 26.3 | 14.05 | ||||||

| Hoisting Height | Freestanding | m | 34 | ||||||||

| Attached | a=2 140 | a=4 70 | |||||||||

| Overall Dimension | Base | m | 5 ×5 ×1.1 | ||||||||

| Total Height | Freestanding | 42.02 | |||||||||

| Attached | 127.02 | ||||||||||

| Distance between Jib Tip to Slewing Center | 51.15 | ||||||||||

| Distance between Balance Arm Tip to Slewing Center | 11.18 | ||||||||||

| Overall Weight | Freestanding (No Counter Weight) | T | 24.71 | ||||||||

| Attached (No Counter Weight) | T | 50.63 | |||||||||

| Counter Weight | T | 10.8 | |||||||||

| Others | Total Motor Power | KW | Single Slewing Mechannism29.9/ Double Slewing Mechannism31.8 | ||||||||

| Wind Speed at Maximum Installation Height | m/s | During Working ≤20 | |||||||||

| During Jacking ≤12 | |||||||||||

| Working Temperature | 0 C | -20 ~ 40 | |||||||||

| Loading Rate | Hoisting Mechanism | JC 40% | ||||

| Slewing Mechanism | JC 40% | |||||

| Trolleying Mechanism | JC 40% | |||||

| Trolleying Mechanism | Motor | Model | YEZS112M -4/8 | |||

| Speed | r/min | 1380 | 720 | |||

| Power | KW | 2.4 | 1.5 | |||

| Reducer | Model | WCJ120 | ||||

| Transmission Ratio | 54 | |||||

| Steel Wire Rope | Specification | 6X19-7.7-1550-FC-SZ, GB8918-06 | ||||

| Line Speed | m/min | 31/16 | ||||

| Trolleying Speed | m/min | 31/16 | ||||

| Hoisting Mechanism | Motor | Model | YZTD200L 4-4/8/24 | |||

| Speed | r/min | 1440 | 720 | 220 | ||

| Power | KW | 18 | 18 | 5 | ||

| Reducer | Center Distance | Mm | 500 | |||

| Transmission Ratio | I | 13.8 | ||||

| Winch Drum | Diameter | Mm | Φ375 | |||

| Layer of Rope | Layer | 4 | ||||

| Rope Capacity | M | 280 | ||||

| Brake | Model | YT1-45Z/5 | ||||

| Braking Force | N | 355 | ||||

| Steel Wire Rope | Traction | N | 12000 | |||

| Specification | 6X19-13-1770-FC-SZ , GB8918-06 | |||||

| Hoisting Speed | m/min | 65/32.5 | 32.5/16 | 10/5 | ||

| Rated Hoisting Capacity | T | 1.25/2.5 | 2.5/5 | 2.5/5 | ||

| Minimum Steady Descending Speed | m/min | ≤7.3 | ||||

| Total Weight | T | 1.05 | ||||

| Slewing Mechanism | Single | Double | ||||

| Motor | Model | YZR160M 1-6 | YZR132M2 -6 | |||

| Speed | r/min | 930 | 910 | |||

| Power | KW | 5.5 | 3.3*2 | |||

| Reducer | Model | XX4-120 | XX4-80 | |||

| Transmission Ratio | I | 180 | 157 | |||

| Output Torque | N ·m | 12000 | 8000*2 | |||

| Wheel Gear | Module | M | 10 | |||

| Tooth Number | Z | 15 | ||||

| Modification Coefficient | X | 0.5 | ||||

| Hydraulic Coupler | Model | YOX320 | YOX280 | |||

| Matched Slewing Bearing | Model | 011.40.1120 | ||||

| Slewing Speed | r/min | 0.61 | 0.6 | |||

| Hydraulic Jacking System | Hydraulic Pump Station | Working Pressure | Mpa | 22 | ||

| Power | KW | 4 | ||||

| Hydraulic Cylinder | Rated Pressure | Mpa | 22 | |||

| Diameter | Mm | Φ140 | ||||

| Rod Diameter | Mm | Φ 90 | ||||

| Stroke | Mm | 1600 | ||||

| Installation Distance | mm | 2048 | ||||

| Jacking Speed | m/min | 0.4 | ||||

| Maximum Jacking Capacity | t | 33 | ||||

| 50m Multiplying 2 | |||||||||||||

| Radius (m) | 3 ~ 24.17 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 |

| Hoisting Capacity (Kg) | 2500 | 2406 | 2302 | 2205 | 2115 | 2031 | 1953 | 1879 | 1811 | 1746 | 1686 | 1629 | 1575 |

| Radius (m) | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 | 49 |

| Hoisting Capacity (Kg) | 1523 | 1475 | 1429 | 1385 | 1344 | 1304 | 1267 | 1231 | 1196 | 1164 | 1132 | 1102 | 1073 |

| Radius (m) | 50 | ||||||||||||

| Hoisting Capacity (Kg) | 1045 | ||||||||||||

| 50m Multiplying 4 | |||||||||||||

| Radius (m) | 3 ~ 12.92 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 |

| Hoisting Capacity (Kg) | 5000 | 4968 | 4589 | 4260 | 3972 | 3718 | 3493 | 3291 | 3109 | 2944 | 2795 | 2658 | 2533 |

| Radius (m) | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 |

| Hoisting Capacity (Kg) | 2418 | 2312 | 2213 | 2122 | 2037 | 1958 | 1883 | 1814 | 1748 | 1687 | 1629 | 1574 | 1522 |

| Radius (m) | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 | 49 | 50 |

| Hoisting Capacity (Kg) | 1473 | 1426 | 1382 | 1340 | 1300 | 1261 | 1225 | 1190 | 1157 | 1125 | 1094 | 1065 | 1036 |

| 44m Multiplying 2 | |||||||||||||

| Radius (m) | 3 ~ 25.23 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 |

| Hoisting Capacity (Kg) | 2500 | 2417 | 2316 | 2222 | 2134 | 2053 | 1976 | 1905 | 1837 | 1774 | 1714 | 1658 | 1605 |

| Radius (m) | 38 | 39 | 40 | 41 | 42 | 43 | 44 | ||||||

| Hoisting Capacity (Kg) | 1554 | 1506 | 1460 | 1417 | 1376 | 1337 | 1299 | ||||||

| 44m Multiplying 4 | |||||||||||||

| Radius (m) | 3 ~ 13.48 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| Hoisting Capacity (Kg) | 5000 | 4803 | 4460 | 4160 | 3895 | 3659 | 3448 | 3259 | 3087 | 2931 | 2789 | 2658 | 2538 |

| Radius (m) | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 |

| Hoisting Capacity (Kg) | 2427 | 2324 | 2229 | 2140 | 2058 | 1980 | 1907 | 1839 | 1775 | 1714 | 1657 | 1603 | 1552 |

| Radius (m) | 39 | 40 | 41 | 42 | 43 | 44 | |||||||

| Hoisting Capacity (Kg) | 1503 | 1457 | 1413 | 1371 | 1331 | 1293 | |||||||

| 38m Multiplying 2 | |||||||||||||

| Radius (m) | 3 ~ 26.3 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 |

| Hoisting Capacity (Kg) | 2500 | 2427 | 2329 | 2238 | 2153 | 2073 | 1998 | 1928 | 1862 | 1800 | 1741 | 1686 | 1633 |

| 38m Multiplying 4 | |||||||||||||

| Radius (m) | 3 ~ 14.05 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 |

| Hoisting Capacity (Kg) | 5000 | 4660 | 4347 | 4071 | 3826 | 3606 | 3409 | 3230 | 3068 | 2919 | 2783 | 2658 | 2543 |

| Radius (m) | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | |

| Hoisting Capacity (Kg) | 2436 | 2336 | 2244 | 2158 | 2077 | 2001 | 1930 | 1863 | 1800 | 1740 | 1684 | 1631 | |

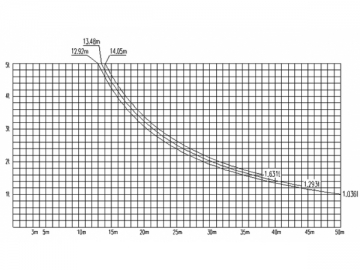

FM5010 Tower Crane Moment Curve (Multiplying 2)

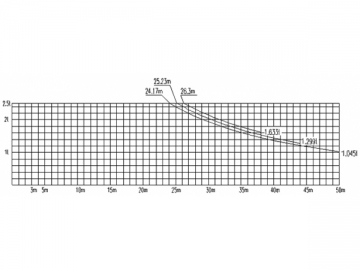

FM5010 Tower Crane Moment Curve (Multiplying 2)