UV Screen Printing Ink

Introduction

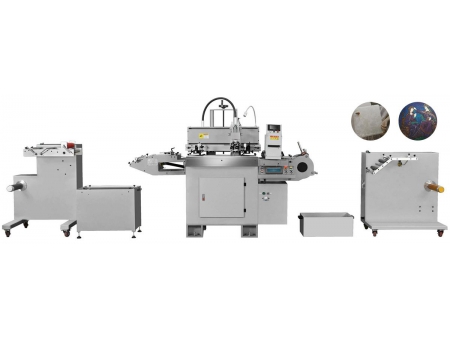

The UV screen printing ink is a new type of UV curable ink developed by KAISHIMEI. It is suitable for gold and silver cardboard, PC, PVC, PET and processed ABS, PE, PP and other plastic substrates. The printed products feature bright and invariant color, good adhesion, wear resistance, etc.

Main Technical Parameters

1. Appearance: sticky liquid

2. Viscosity: 5000 200 cps (25 ℃ NDJ viscosity measurement)

3. Weight: 1.1 ~ 1.2 g/cm3

4. Solid content: more than 99%

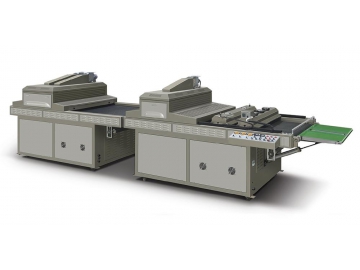

5. Dry conditions: 3 ~ 5min (80w/cm medium pressure mercury lamp 3 pcs)

6. Storage period: 6 months

Use and Precautions of UV Screen Printing Ink

1. The number of screen printing mesh is 250~350 (100T-120T) and blade hardness is 70 degrees.

2. The UV silk-screen printing ink can be properly diluted according to user’s actual needs. 5-10% diluting is appropriate (our company offers special diluting agent).

3. Ink in the print work should be diluted before or after full mix.

4. The ink must be thoroughly cured so that it can be easy to bond, avoiding unstable bonding.

5. The color can be adjusted according to customers.

6. This product should be placed in dry and cool place and avoid hot.

7. After the printing is dry, this product has without any pollution and stimulate.