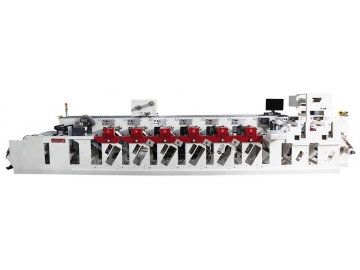

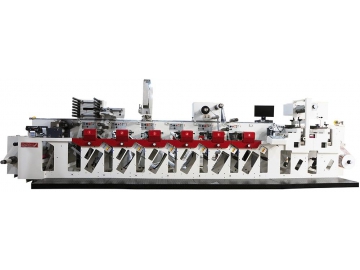

UV Flexo Ink

Our UV flexo ink is suitable for white cardboard, gold and silver cardboard, PET coated cardboard, laser cardboard and special paper for cigarette packaging. In addition to these, the UV ink is applied to synthetic paper, self-adhesive labels, PVC, PET, PE, PP and other materials.

Good product examples of this flexographic ink in point are senior packaging cosmetics, cigarettes, wine, trademark, plastic stationery, all kinds of plastic products, etc.

Printing Effect Characteristics

1. Exposed to the UV light, the ink can be cured instantly without back printing or sticky and dirty problems.

2. The adhesion of most non-absorbent substrate is great.

3. High strength and high fullness color can be ensured.

4. The product surface printed by our UV flexo ink features excellent sharpness of dots and great resistance to friction and scratch.

5. Ink transfer is good and ink film has good flexibility.

Technical parameters

Adhesion 100%

Viscosity (25℃): 8-15P 5 μ m

Diameter: 26-38cm/s, 2-4m/s

UV: 120w/c

Method of Use

1. Special UV 1-5%; adding ink oil can reduce the ink viscosity and increase the flow of ink.

2. To reduce the color concentration, you can add UV withdrawal of diluting agent.

3. Less than 5% UV adhesives can be added to decrease viscosity and drawing.

4. The UV flexo ink can be used in offset printing and rotary printing.