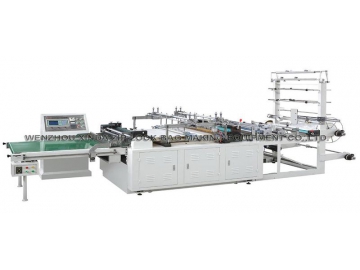

CW-600 BSC, CW-1000 BSC Bottom Weld Bag Making Machine

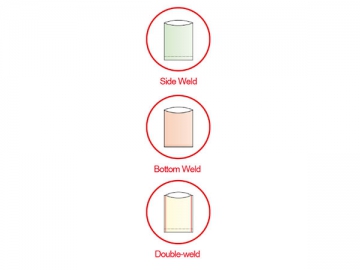

Our range of bottom weld bag making machine can be employed in making heat sealing cold cutting bottom sealing bags. It can be provided in various models, given the size of the bags. The maximum bag making length reaches 2 m.

The bottom sealing bag making equipment comes with one set of stepper motor and driver. With one photocell tracking system, it is great for both printed and unprinted bags. The different types of bottom weld bag made by this product can be commonly seen in supermarkets, department stores, etc. Furthermore, they can be used for packing clothes, shoes, gifts and so on. Our bottom sealing bag making machinery can also be optionally equipped with a set of servo motor and driver.

Characteristics

1. The total control panel of the plastic bag making machine adopts a human computer interface. The touch screen from Taiwan is used for real-time display.

2. The drive system of the whole product adopts the single chip control.

3. The product comes with the 1.5kW Japanese Yaskawa inverter.

4. The bottom weld bag making machine makes use of C type channel steel welding frame.

5. It has an intelligent temperature controller with double digital displays. All the heating operations are dominated by the solid relay.

6. The stepping motor is responsible for material dragging.

7. The maximum single unwinding diameter is 500mm. The unwinding roller is the air shaft.

| Model | |||

| Width of bag making | 600mm | 800mm | 1000mm |

| Length of bag making | 1000mm | 1000mm | 1000mm |

| Speed of bag making | 40-130pcs/min | 40-130pcs/min | 40-130pcs/min |

| Total power | 3.5KW | 4KW | 4.5KW |

| Machine weight | 800KG | 900KG | 1000KG |

| Machine dimension(L*W*H) | 3300*1040*1600mm | 3300*1240*1600mm | 3300*1450*1600mm |

Note: The above technical specifications, performance characteristics as well as appearance can be possibly changed owing to our ceaseless perfection of existing products as well as new functions. Please understand that if there is no further notice.