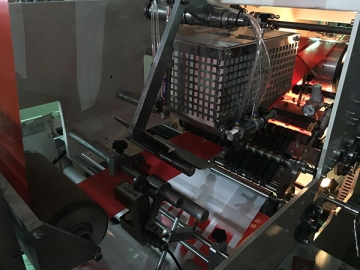

CW-300NT2, CW-400NT2 Plastic Vest Carrier Bag Making Machine

Features

1. This range of plastic vest carrier bag making machine is a kind of heat sealing and heat cutting equipment especially designed for plastic shopping bag making in a fully automatic and computer controlled way.

2. It comes with 2 stepper motors and relevant driving system for material transmission. The shopping bag making equipment can also be configured with Japanese servo motor and corresponding driving system. Additionally, the driving system is subject to the regulation of a single chip microcomputer.

3. There are two photocell tracking mechanisms and two sets of fully automatic handle puncher for production of two lines of printed or unprinted bags.

4. The product adopts the hydraulic automatic punching.

5. All the operation parameters are shown by the Taiwan made touch screen with fully automatic design.

6. The plastic vest carrier bag making machine chooses the double digital intelligent temperature controller and the heating operation is controlled by the solid relay.

7. The product is equipped with the frequency converter produced by the Japanese Yaskawa.

8. The clamping of bags is under the control of the AC inverter motor.

9. The DC motor works for film feeding.

| Model | ||

| Max. Bag Making Width | 300mm×2 lines | 400mm×2 lines |

| Max. Bag Making Length | 500-600 mm×2 | 500-600 mm×2 |

| Bag Making Thickness | 0.01-0.05 mm | 0.01-0.05 mm |

| Bag Making Speed | 130 pieces×2 | 130 pieces ×2 |

| Total Power | 5.5kW | 6.5kW |

| Weight | 1400 kg | 1600 kg |

| Machine Dimension (L×W×H) | 6000×1400×1600 | 6000×1600×1600 |

Note: The appearance, performance features as well as technical parameters can be possibly changed without further notice, due to our ceaseless improvement of existing machines as well as development of new functions.

Related Names

Twin Lane T-shirt Bag Making Machine | Automatic T-shirt Bag Making Machine