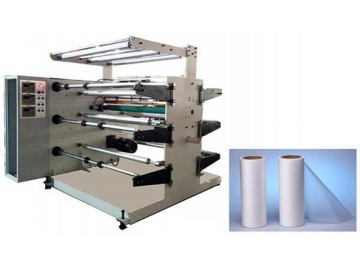

Toilet Paper Rewinding, Perforating, Slitting Line

The HX-2800B fully automatic toilet paper production line combines rewinding, perforating and slitting machines into one for a more efficient production process.

Features of toilet paper rewinding and perforating machine

1. This toilet paper production line uses a PLC to control the entire production flow, and it automatically trims edges, sprays glue, rewinds toilet paper and changes paper cores without stopping.

2. Our toilet paper rewinding, perforating and slitting line regulates its speed automatically when changing jumbo rolls. Its rewinding force is large at the beginning of the process and then lessen to avoid separating the paper from the core.

3. This paper machine will automatically alert operators to add paper cores when necessary and will stop automatically if there is no paper core or jumbo roll available, or if the jumbo roll breaks.

4. All jumbo rolls are loaded pneumatically, and our toilet paper rewinding, perforating and slitting line has two jumbo roll stands. Moreover, a specialized device attached to the line can manufacture toilet paper rolls without cores.

Technical Data of of toilet paper rewinding and perforating machine

1. Production speed: About 120-180m/min

2. Installed power: About 15.3kW (380V/50Hz)

3. Jumbo roll width: ≤2800mm

4. Jumbo roll diameter: ≤1200mm

5. Jumbo roll weight: ≤800kg (other values are provided upon request)

6. Paper weight: 13-20g/m2 for two-ply type, 20-40g/m2 for one-ply type

7. Finished paper roll diameter: ≤100-130mm

8. Finished paper roll width: 90-120mm

9. Perforation interval: 100-150mm

10. Machine weight: About 7 tons

11. Machine dimensions (L×W×H): 6630×3600×1900mm

Technical Data of toilet paper cutting machine

1. Jumbo roll length: 1500-2000mm

2. Jumbo roll diameter: 100-120mm (customizable)

3. Production speed: 80-100 times/minute × 2 slitting /time

4. Power consumption: 6.77kW (380V/50Hz)

5. Machine weight: About 2 tons

6. Machine dimensions (L×W×H): 8500×1200×1920mm