Toilet Paper Production Line

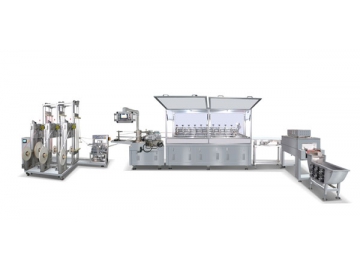

The HX-1575B Fully Automatic Toilet Paper Production Line produces both toilet paper and kitchen paper rolls (with or without a paperboard core), and is composed of three parts: toilet paper embossing, rewinding and perforating machine, fully automatic paper roll slitter machine, and an automatic toilet roll packing machine.

Features of fully automatic toilet paper production line

1. All operations, from unwinding to packaging, are done using the assembly line manufacturing process and needs only 2-3 operators to monitor the production.

2. This paper converting equipment includes a specialized packing machine which uses printed plastic films to pack finished paper rolls while forming a handheld plastic bag at the same time. In this way, packing cost is cut down since you don't need to buy expensive finished packing bags. Additionally, the packing machine is able to pack 4, 6, 8, or 10 toilet paper rolls at once or 2 or 4 kitchen towel rolls.

3. Our toilet paper and kitchen paper production line is simply designed and easy to use at an affordable cost.

Production Process of fully automatic toilet paper production line

1. Toilet Paper: Unwinding jumbo rolls - embossing - perforating - rewinding - tail sealing - cutting - packing

2. Kitchen Towel Rolls: Unwinding jumbo rolls - embossing - perforating - rewinding - tail sealing - cutting - packing

System Composition of fully automatic toilet paper production line

The toilet paper production line consists of the following three major parts.