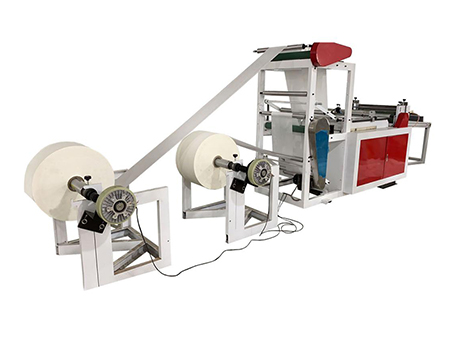

Automatic Aluminum Substrate Layer Sheeting Stacking Cutting System

Aluminum substrate is stacked using copper foil, prepreg and aluminum plate, and LEAD machinery optimizes this process based on return line principles to achieve a fully-automatic operation, including cutting of copper foil, stack-up of aluminum plate, as well as breakdown, cutting and packaging of semi-finished aluminum substrate.

Manufacturing processThe aluminum substrate stacking Cutting machine uses a manipulator to achieve automatic multiple layering of aluminum plate, prepreg and copper foil, and then conveys them through press loading equipment to laminate them. The resulting semi-finished aluminum substrate is separated by manipulator, cut and finally packaged by automatic packaging machine.

- Automatic stack-up

- Automatic breakdown

- Automatic cutting

- Automatic steel plate returning

Custom designing

Considering the workshops and demands of different customers, the layer stacking machine can be manufactured with custom designs and requirements, so as to effectively avoid the problems of oxidation, pitting, wrinkle and poor cutting in the process of aluminum substrate production.

Automatic production

Aluminum substrate production line can achieve cutting and stacking with high automation.

Low energy consumption

In order to decrease energy consumption, the capacity of every unit is calculated and custom designing is essential.

Uses

Automatic arranging of plates

- Stacking mode: automatic stacking of copper foil/prepreg with rubber film and aluminum substrate;

- Stacking accuracy: ±1.5mm;

- Stacking speed: 8 seconds/layer

Uses

Cutting aluminum substrate

- Cutting speed: 10 layers/second

- Cutting mode: The manipulator transfer semi-finished aluminum substrate to cut in cutting unit, and then collect the aluminum substrate.

Uses

Collecting aluminum substrate

- Stacking mode: laying up alternately;

- Intelligent control: achieve remote monitoring, reserve PLC interface and ERP interface.