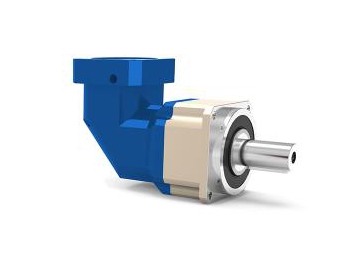

VRL Precision Speed Reducer

Gantry type machine tool, laser cutting machine, wood engraving machine, full servo paper towel machine, precision concave convex printing press, precision coater, servo pipe bender, CNC spring machine, belt conveyer, carton packer, packing machine, dispensing robot, loading robot, turret.

| Model No. | Unit | Stage | Ratio | VRL050 | VRL070 | VRL090 | VRL120 | VRL155 | VRL205 | VRL235 |

| Rated Output Torque | Nm | 1 | 3 | 20 | 55 | 130 | 208 | 342 | 588 | 1140 |

| 4 | 19 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 5 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 6 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 7 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 8 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 9 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 10 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 2 | 15 | 20 | 55 | 130 | 208 | 342 | 588 | 1140 | ||

| 20 | 19 | 50 | 140 | 290 | 542 | 1050 | 1700 | |||

| 25 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 30 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 35 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 40 | 17 | 45 | 120 | 260 | 500 | 1000 | 1600 | |||

| 45 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1200 | 2000 | |||

| 60 | 20 | 55 | 150 | 310 | 600 | 1100 | 1900 | |||

| 70 | 19 | 50 | 140 | 300 | 550 | 1100 | 1800 | |||

| 80 | 17 | 45 | 12 | 260 | 500 | 1000 | 1600 | |||

| 90 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 100 | 14 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| Max. Output Torque | Nm | 1,2 | 3-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 3-100 | 5000 | 5000 | 4000 | 4000 | 3000 | 3000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 3-100 | 10000 | 10000 | 8000 | 8000 | 6000 | 6000 | 4000 |

| Micro Backlash P1 | Arcmin | 1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 15-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Precision Backlash P2 | Arcmin | 1 | 3-10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| 2 | 15-100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 3 | 7 | 14 | 25 | 50 | 145 | 225 |

| Max. Radial Force | N | 1,2 | 3-100 | 680 | 1260 | 2880 | 6000 | 8200 | 12800 | 27800 |

| Max. Axial Force | N | 1,2 | 3-100 | 330 | 625 | 1250 | 2400 | 3890 | 6100 | 15000 |

| Service Life | Hr | 1,2 | 3-100 | 20000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||||

| 2 | 15-100 | ≥94% | ||||||||

| Weight | Kg | 1 | 3-10 | 0.5 | 1.2 | 3.5 | 7.8 | 14.5 | 30 | 50 |

| 2 | 15-100 | 0.8 | 1.4 | 4.1 | 9 | 17.5 | 33 | 63 | ||

| Operating Tempwerature | ℃ | 1,2 | 3-100 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤56 | ≤58 | ≤60 | ≤63 | ≤65 | ≤67 | ≤70 |

1.No noise

Using bevel wheel for revolving smoothly.

2.High precision

The backlash is less than 3 arc for accurate positioning.

3.High rigidity and high torque

Improving the inertia and torque largely under using integral ball bearing.

4.Using flange as connection mode

This reducer can be installed on any motor in the world

5.No leakage of lubricating grease

Using lubricating grease which is of high viscosity and not easy to be separated for preventing leakage of lubricating grease.

6.Easy maintenance

Install easily and don't need to replace lubricating grease in the life of product.

1.We use the technology of ANSYS to do finite element analysis for gear strength and trim the teeth and lead of tooth surface in order to reduce the impact and noise of gear mesh and increase working life of gear trains.

2.The gear is made of superior alloy steel which is dealt with carbonitriding for best abrasive and impact resistance.

3.The output planet carrier adopts one-piece(double bracing) structure design and the front and rear bearings are distributed in the box in a large span. So, there is one-piece stable structure to ensure high torsional rigidity and precision.

4.The gear ring and output shell are made of quality steel products and have high material density under hot forging. Compared with embedded and clamping structure, the gear ring and output shell adopt one-piece structure design which can make sure that all geometric dimensions are processed at one time for higher precision and strength.

5.The input axis and locking device use one-piece design. The double bolts are symmetrically distributed, so it can achieve the dynamic balance and prevent the motor shaft from slipping when transmitting and realize the power transmission with high precision and zero backlash due to the strong locking of the double bolts.

1. How to install the gearbox.

Step 1: Wipe off the anti-rust agent and grease on the motor shaft

Step 2: Remove the rubber plug

Step 3: Turn the input shaft until the cap screw is seen. Make sure the cap screw is loosened.

Step 4: Please place reducer vertically on a flat surface, leaving the surface of the motor mounting upwards. Carefully insert the motor shaft into the input shaft (it should insert smoothly). Make sure the motor flange fits perfectly to the reducer flange. Tighten the motor mounting bolt as per appointed fastening torque.

Step 5: Tighten the clamping bolt of the input shaft with a wrench according to the suggested torque.

Step 6: Re-install the rubber plug. Finish the installation.

2. How to store the reducer?

1) Keep the reducer in a clean and dry place.

2) If it will be stored outdoors or in a humid place, please put the reducer in a box packed tightly with a plastic bag to avoid exposure to natural elements. (take any additional anti-condensation and anti-rust measures)

3. Caution for operation:

1) Please confirm the reducer model number is the same as the one you ordered when the reducer is delivered.

2) The reducer was already filled with lubrication oil. You can use it right now.

3) During initial operation, please confirm the rotation direction of the output shaft, then increase the load little by little.

4. Caution during operation:

1) Do not overload!

2) Input speed cannot exceed the proper max. speed.

3) Please stop and check the reducer if any of the following occurs:

Sudden temperature rise

Abnormal noise

Unstable speed

5. Warranty instruction:

The following cost and damages are not included in our warranty:

1) Freight cost

2) If the Reducer connects with or inserts in a unit, when we dismounting or mounting on the unit and other extra action, there will be a cost. (this is not covered in the warranty)

3) The indirect damage that user lost the appliance chance or business break off due to reducer breakdown.

4) Other derivative and accompanying damages.