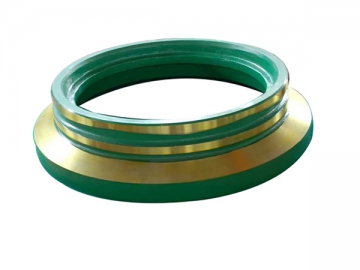

Mantle Liner

Cone Crusher Part

Part name: Mantle liner

Applicable machine: Cone crusher

Raw materials: High manganese steel

Applications: The precision cast parts are crucial parts for cone crushers and play an essential role in crushing ores and rocks of high hardness and medium hardness, including iron ores, limestone, copper ores, quartz, granite, sandstone, etc.

Customized or not: Yes

Mantle liner models: Customized to cone crusher models, drawings, samples or customers' requirements.

Order quantity: not limited

Parts Introduction

Mantle liner is one of the major wear parts of cone crusher. Cast from advanced composite materials, it features ultra high wear resistance, excellent cost effectiveness, extensive applications, and other advantages. The cone crusher mantle is fixed to the cone, with epoxy resin poured to the gap between them. After newly installed or newly changed mantle works for 6-8 hours, it is necessary to check whether it is fastened or not. If not, fasten it as soon as possible.

When cone crusher is working, the mantle liner and concave liner form an annular charmer in which materials will be continuously squeezed, impacted and crushed.

Mantle liner models: Customized to cone crusher models, drawings, samples or customers' requirements.

Order quantity: not limited

Parts Introduction

Mantle liner is one the major wear parts of cone crusher. Cast from advanced composite material, it features ultra high wear resistance, excellent cost effectiveness, extensive applications, and other advantages. The cone crusher mantle is fixed to the cone, with epoxy resin poured to the gap between them. After newly installed or newly changed mantle works for 6-8 hours, it is necessary to check whether it is fastened or not. If not, fasten it as soon as possible.

When cone crusher is working, the mantle liner and concave liner form an annular charmer in which materials will be continuously squeezed, impacted and crushed.

Technical Parameters

(Following table shows the parameters of concave liners and mantle liners that we have customized to customers' requirements. For other specifications, please contact us directly)

| Model | Name | Large opening diameter (mm) | Small opening diameter (mm) | Height (mm) | Weight (Kg) |

| Concave liner | 1226 | 969 | 427 | 627 | |

| Mantle liner | 1106 | 435 | 380 | 593 | |

| Concave liner | 1225 | 968 | 430 | 633 | |

| Concave liner | 1070 | 770 | 434 | 403 | |

| Concave liner | 1063 | 784 | 397 | 350 | |

| Mantle liner | 963 | 300 | 428 | 374 | |

| Concave liner | 1060 | 800 | 422 | 554 | |

| Mantle liner | 982 | 275 | 460 | 422 | |

| Concave liner | 1060 | 800 | 358 | 527 | |

| Concave liner | 1060 | 800 | 359 | 515 | |

| Concave liner | 1060 | 800 | 364 | 503 | |

| Mantle liner | 974 | 280 | 463 | 480 | |

| Concave liner | 1060 | 800 | 389 | 528 | |

| Mantle liner | 1161 | 300 | 554 | 791 | |

| Concave liner | 1240 | 940 | 429 | 763 | |

| Concave liner | 1240 | 940 | 438 | 745 | |

| Concave liner | 1240 | 940 | 466 | 860 | |

| Mantle liner | 1066 | 453 | 520 | 500 | |

| Mantle liner | 1160 | 470 | 900 | 954 | |

| Mantle liner | 1203 | 463 | 563 | 754 |