Automatic Oral Thin Film Making Machine

Request a Quote

OZM-340

The automatic oral thin film making machine is specifically used to turn liquid materials into thin film. It is applicable to make fast dissolving oral films, transfilms, and mouth freshener strips, having wide application range in pharmaceutical field, food industry and etc.

Technical Specifications

| Items | Parameters |

| Model | OZM-340II |

| Max. film width | 360mm |

| Roll width | 400mm |

| Machine speed | 0.1m-1.5m/min (depending on formula and process technology) |

| Unwinding diameter | ≤Ø350mm |

| Winding diameter | ≤350mm |

| Method of heating & drying | Heating by external stainless steel heater, hot air circulation with centrifugal fan |

| Temperature control | 30~80℃±2℃ |

| Edge of reeling | ±3.0mm |

| Power | 16kW |

| Overall dimension ( L×W×H) | 2980*1540*1900mm |

Features of Oral Films

- High dosing accuracy

- Fast dissolving

- Quick releasing

- No swallowing difficulty

- High acceptance by elderly and children

- Small size convenient to carry

Working Principle

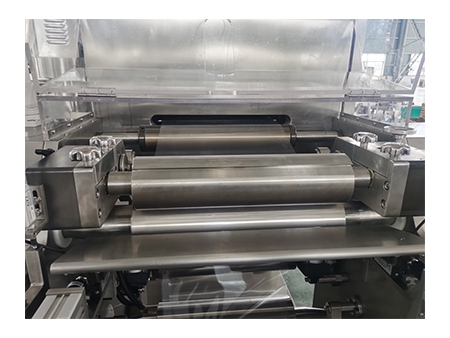

The working principle of the automatic oral thin film making machine is evenly coating a layer of liquid material on the surface of the base roll. The solvent (moisture) is rapidly evaporated and dried through drying channel. Then, winding is carried out after cooling (or composite with another material). Last, the final films (composite films) are obtained.

Performance & Features

- Servo speed regulation system is adopted in this oral thin film making machine, and the magnetic powder brake is used in unwinding unit for tension control.

- Modular design allows individual modules to be assembled and dismantled easily. Cylindrical locating pins enable assembling more conveniently and tightly.

- The oral thin film machine automatically registers working length and displays working speed.

- The drying chamber is divided into compartments with the function of independent automatic control of temperature, humidity and concentration, ensuring high work efficiency.

- Lower driving zone and upper operation zone are completely separated by means of stainless steel plate, effectively protecting two areas from cross-contamination during oral thin film production, while facilitating machine cleaning process.

- All parts in contact with materials, including rollers and drying channel, are made from 316 stainless steel in full compliance with the requirements of GMP standard.

- All electrical components, wiring and operation methods are UL certified, guaranteeing high safety.

- Emergency stop switch enhances operator's safety when operating the oral thin film machine or changing molds.

- The entire production process including unwinding, coating, drying and rewinding is continuously carried out, without the need for manual assistance, thus greatly improving production efficiency while reducing labor intensity.

- A separated structure design allows that the drying chamber can be manufactured to customer-specific length.