Vegetable Oil Pretreatment and Pressing Line

We are always designing and manufacturing vegetable oil pre-treatment and pressing line based on characteristics of different vegetable oils as well as customers’ requirements. In this way, we are able to ensure optimum conditions of the oil obtained by enhancing oil yield, improving protein content and oil quality.

Production Sections and Major DevicesMajor Devices: automatic unloading machine, cleaning and classifying screen, elevator for delivering goods into silos, horizontal conveyor and conveyor for taking goods out of silos

Major Devices: flat classifying screen, specific-gravity stoner, online meter and magnetic separator for iron removal

Major Devices: magnetic separator for iron removal, crusher (huller) and kernel and husk separator

Features of kernel and husk separator

Inverter-driven feeding device is able to ensure even distribution of materials. An air-lock valve is installed at the feeder to guarantee normal feeding. Generally, soybeans or other seeds will be thrown against each other from various directions, which results in intense collision. Hence, hulling efficiency is highly improved. Furthermore, wind and mixture of kernel and husk run towards each other to ensure full contact, thus significantly improving husk removal efficiency. A vision glass is also equipped on the separator for real time observation of hulling and separating process.

Major Devices: automatic control box for material level, magnetic separator for iron removal, flaking mill, hydraulic driving station and conveyor

Applicable Oil Materials: soybeans, rapeseeds, cottonseeds, sunflower seeds, maize germs

Production Capacity per Flaker: 80-500t/d

Features of Flaking Mill

The flaking mill features user friendliness, stable performance and easy maintenance. It is able to ensure automatic control of material level, inverter-driven feeding mode and uniform material layout. It is fitted with a reversible powerful magnet, thus making it convenient to remove impurities attached to the magnet. Flakes obtained features equal thickness, which is in range of 0.25 to 0.35mm.

3, 000t/d soybeans flaking process

3, 000t/d soybeans flaking process

Major Devices:drying and conditioning tower, crusher (huller) and kernel and husk separator

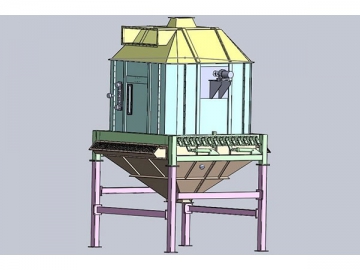

Features of Drying and Conditioning Tower

With modular structure, the tower is made up with drying section and conditioning section. It is can be easily assembled to accommodate different materials and various production processes. Each layer of the tower is equipped with vision glass for observation of materials status inside. In the tower, a micro-negative pressure working environment is created by scientific settings of forced draft and induced air. In this way, dust can be efficiently prevented from leaking out the tower to protect the environment.

The feeding device comes with two silos, which split feed into two streams and ensure uniform materials layout. Furthermore, impact imposed on the tower by materials accumulation can be eliminated. The discharging device features frequency control, thereby ensuring uniform and stable discharging. For safety and stable operation, it is essential to keep materials levels at feeding and discharging ports in normal range. Hence, alarm devices are applied for control of materials levels.

Designed with high heat transfer efficiency, stainless flat tubes used in the heating section also greatly facilities material flow. Hence, materials will fully contact with thermal medium, which furthers enhance drying and conditioning effect. Moreover, circulating countercurrent hot wind is used as heat source for full heat utilization, thus improving drying efficiency and saving energy.

Major Devices: horizontal drum softening machine, supplementary conveying equipment for feeding and discharging

Applicable Oil Materials: soybeans, rapeseeds, cottonseeds

Production Capacity: 100-1,500t/d

Features of WRG-B Series Horizontal Drum Softening and Conditioning Machine

WRG-B series horizontal drum softening and conditioning machine is one of our patented products. It consists of rotating heating element, air intake system, drainage system, automatic air extraction system and transmission system. The drainage system is specially designed to ensure continuous drainage of all condensate water. As a result, it is able to prevent water from accumulating in bottom tubes contacting materials processed directly. An automatic air extraction valve is installed at the top of the softening machine to expel non-condensable gases, which impede heat transmission. The machine is fitted with an variable frequency motor. The conditioning time is adjustable.

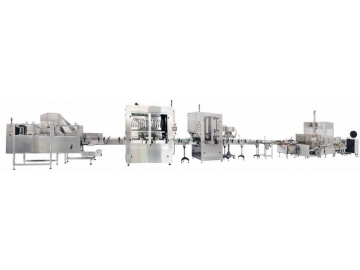

Major Devices: horizontal drum softening machine, flaking mill, cooker, oil press, flakes cooling machine, crude oil filtering system

Applicable Oil Materials: soybeans, cottonseeds, sunflower seeds, maize germs, camellia seeds

Production Capacity: 50-3000t/d

Major Devices: feeding conveyor, magnetic separator for iron removal, extruder, drying and cooling system

Applicable Oil Materials: soybeans, rapeseeds, cottonseeds

Production Capacity: 50-6,000t/d

Major Devices: feeding conveyor, air-lock valve, wearing flow dryer, flap dry cooling machine, draught fan and air heater

Applicable Oil Materials: extruded soybeans, rapeseeds, cottonseeds

Production Capacity: 100-6,000t/d