Cottonseed Miscella Refining Line

Major Device

Filter, evaporator, acid metering pump, alkali metering pump, acid reactor,alkali reactor,disc centrifuge, heat exchanger, desolventizing device, vacuum system, holding tank, electrical control equipment.

Features

In order to simplify production process and save steam, refining and desolventizing processes are all carried out directly in the leaching workshop to produce third-grade cottonseed oil. Our refining line is also able to efficiently prevent pigment consolidation caused by high temperature and eliminates common difficulties of refining. The refined oil obtained features brighter color and higher quality than any other refining processes. The refined miscella can efficiently withstand emulsification, which hinders soap from entering the neutral oil and further reduces neutral oil loss. As a result, high refining yield can be achieved. Evaporators and dryers adopted are capable of prevent dirt from accumulating on them, which ensures high evaporation efficiency and decreases cleaning frequency. The whole refining process almost doesn’t create any waste water or water solids, which contributes to environment protection.

Raw Materials: cottonseed flakes produced by an extruded cottonseed extraction line

Production Capacity: 100-1000t/24h cottonseeds

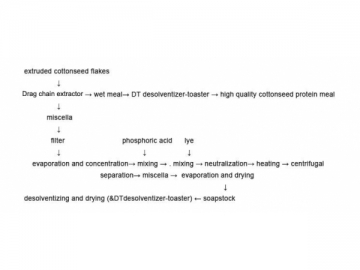

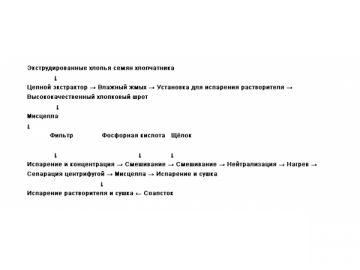

Neutralization and saponification process for miscella refining line matched with 600t/d extruded cottonseed extraction line

Evaporation process miscella refining line matched with 500t/d extruded cottonseed extraction line

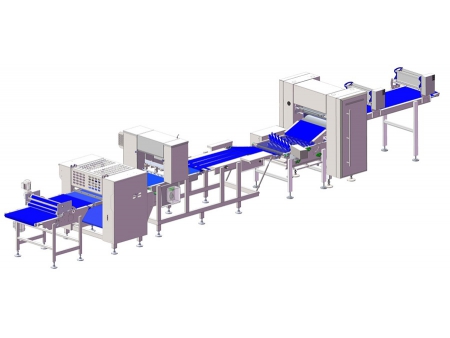

600t/d extruded cottonseed extraction plant layout