Molybdenum Fabricated Products

We provide a variety of forms and dimensions for molybdenum fabricated products. Shown below are most of the standard stock forms/sizes. If you do not see the size or form of the molybdenum that you require, please contact one of our material experts. They are all experts in their fields and can assist you in finding the right molybdenum plate, sheet, rod or wire for your needs. We can also cut, slit, shear, or centerless grind molybdenum to exact customer specifications. Customization in sizes, packages and unusual materials is also easy.

Product applications

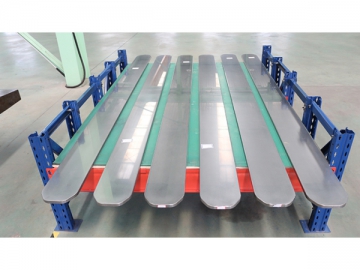

Molybdenum plates belong to refractory materials and are widely used in electric furnaces and accessories, electronics and semiconductors.

| Molybdenum Plates | |

| Purity | 99.95% Min. |

| Density | 10.15g/cm3 |

| Length | ≤ 3000mm |

| Width | 3-50mm |

| Thickness | ≤ 600mm |

| Grade | Content of Mo (%) | Other elements | |||||||||||

| Pb | Bi | Sn | Sb | Cd | Fe | Ni | Si | Ng | C | O | Nv | ||

| Mo-1 | 99.9 | 0.001 | 0.001 | 0.001 | 0.005 | 0.001 | 0.005 | ----- | 0.002 | 0.002 | ----- | ----- | 0.003 |

| Mo-2 | 99.5 | 0.001 | 0.001 | 0.001 | 0.005 | 0.001 | 0.005 | 0.003 | 0.002 | ----- | 0.005 | 0.003 | 0.003 |

| Mo-3 | 99.5 | 0.001 | 0.001 | 0.001 | 0.005 | 0.001 | ----- | ----- | ----- | ----- | 0.005 | 0.003 | 0.003 |

| Mo-4 | 99.5 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | ----- | ----- | 0.002 | ----- | ----- | ----- | 0.003 |

| Grade | Examples of application |

| Mo-1 | Fine processing of raw material |

| Mo-2 | General processing of raw material |

| Mo-3 | A lloy additive |

| Mo-4 | A lloy additive |

Usage

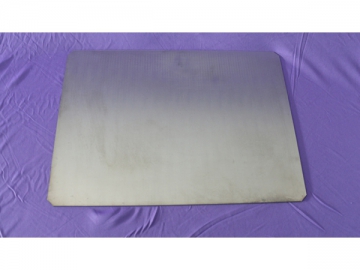

Thinner than a molybdenum plate, the molybdenum sheet is widely used to make ceramics, heaters, and rare earth magnetic materials.

| Molybdenum Sheets | |

| Purity | 99.95% Min. |

| Density | 10.15g/cm3 |

| Length | ≤ 3000mm |

| Width | 0.05-3mm |

| Thickness | ≤ 600mm |

| Thickness (mm) | Tolerance | Width (mm) | Tolerance | Length (mm) | Tolerance |

| 0.10-0.15 | ±0.02 | 50-200 | ±2 | 100-1200 | ±5 |

| 0.15-0.30 | ±0.03 | 50-200 | ±2 | 100-1200 | ±5 |

| 0.30-0.50 | ±0.04 | 50-200 | ±2 | 100-1200 | ±5 |

| 0.50-0.70 | ±0.05 | 50-600 | ±3 | 100-1200 | ±5 |

| > 0.70 | ±0.10 | 50-400 | ±5 | 100-1200 | ±5 |

| > 5.0 | ±0.20 | 50-400 | ±5 | 100-1200 | ±5 |

| Grade | Content of Mo ( %) | Other elements ( %) | |||||||||

| Fe | Ni | Al | Si | Ca | Mg | C | O | N | Ti | ||

| Mo1/JMo1 | Rest | 0.001 | 0.005 | 0.002 | 0.010 | 0.002 | 0.002 | 0.010 | 0.008 | 0.003 | ----- |

| Mo2 | Rest | 0.015 | 0.005 | 0.005 | 0.010 | 0.004 | 0.005 | 0.020 | 0.020 | 0.003 | ----- |

| MoTi0.5 | Rest | 0.01 | 0.005 | 0.002 | 0.010 | 0.004 | 0.002 | 0.01-0.04 | 0.003 | 0.001 | 0.4-0.6 |

Usage

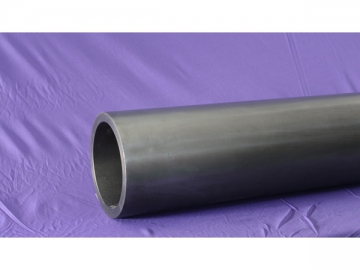

The appearance is silvery gray with a metallic luster. The molybdenum rod is made from raw materials of the M0-1 molybdenum powder and is most often sed to make heaters and stun guns.

| Molybdenum Rods | |

| Purity | 99.95% Min. |

| Density | 10.0g/cm3 |

| Length | ≤ 3000mm |

| Diameter | 2-300mm |

| Grade | Content of Mo ( %) | Other elements ( %) | ||||||||||||||

| Pb | Bi | Si | Sb | Cd | Fe | Ni | Al | Si | Ca | Mg | P | C | O | N | ||

| Mo-1 | 99.95 | ----- | ----- | ----- | ----- | ----- | 0.005 | 0.002 | 0.002 | 0.003 | 0.002 | 0.001 | 0.001 | 0.003 | 0.003 | 0.001 |

| Mo-2 | 99.95 | ----- | ----- | ----- | ----- | ----- | 0.006 | 0.001 | 0.002 | 0.003 | 0.002 | 0.001 | 0.001 | 0.003 | 0.005 | 0.003 |

| Mo-3 | 99.95 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.005 | 0.005 | 0.005 | 0.003 | 0.004 | 0.003 | 0.002 | 0.010 | 0.006 | ----- |

Uses

Molybdenum wire is used for heating wire and electrodes. It is also widely used in filaments.

| Molybdenum Wire | |

| Purity | 99.95% Min. |

| Density | 0. 1 5g/cm3 |

| Length | ≤ 3000mm |

| Diameter | 0.5-3mm. |

| Element | Mo | O | N | C | Si | Fe |

| Content ( % ) | ≥99.95 | ≤0.006 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.01 |