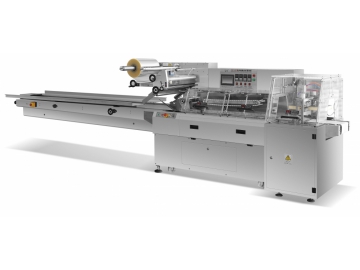

Flow Pack Wrapping Machine, HFFS Pack Wrapper, DXD-630W Horizontal Wrapper Equipment

DXD-630W horizontal wrapper equipment is a flexible piece of machinery designed for the packaging of products such as hamburgers, instant noodles, household products, medical products, and so on.

We provide two kinds of flow pack wrapping machine, the HFFS pack wrapper and VFFS pack wrapper.

TheDXD-630W horizontal wrapper equipment is a reciprocating type horizontal flow pack wrapping machine (HFFS). In this packaging process, the packaging film is first sealed, and then it is cut after transported traveling a set distance. This kind of pack form guarantees a delicate package appearance, good integrity preservation and freshness of the product.

The pack form of the DXD-630W is up-film packaging. In addition, we provide a variety of packaging films. The DXD-630 packaging machine can be used to package large items with a width over 80mm and thickness over 5 cm.

Controlled by 3 servo motors, the DXD-630W consists of an infeed machine, shrink wrapper and cutting unit. The feeding, forming and sealing are fully automatic. This design can guarantee the stability of the conveyor belt speed, package integrity and production output.

The conveyor belt feeder and arranging machine are both made of stainless steel or PVC which has been designed to ensure hygienic packaging and protect the items from contamination.

The feeder can be directly connected with the food production line, which enhances production efficiency and speed. The pack width can be changed according to the size of the food being packed. The packaging machine can be equipped with different conveyors to match with food production lines of different widths.

The setting of the neutral gear of the conveyor can prevent the falling and deforming of the food at the turning point.

- With a high-speed automatic film joining device, one roll of packaging films and another spare one, the pack module can realize working continuously without idling.

- The position of the packaging film on the conveyor belt can be manually adjusted to guarantee the integrity of the package.

- The tension of the film can be adjusted manually based on different film properties to make sure the packaging fits tightly.

- The photoelectric sensor has the function of identifying patterns automatically so that the printing pattern quality is guaranteed. The function of marking the horizontal seal position ensures accurate cutting. Besides that, it can print the production date.

- The photoelectric sensor and program settings can control the length of the packing bags.

- Former - Cover the packaged items with the film.

- Fin seal brushes - Squeeze and empty the air in the packing bag, slow down the thrust speed of the feeding claws, and make sure the smooth and uniform transportation and improve packaging yield.

- End seal brushes - realize the fixation of the packaging items to help the transportation and emptying needless air. The end seal brushes drive the synchronous belt so that it has the advantages of low noise, no rust, no contamination, lower price as well as easier dis-assembly and replace.

- Vertical seal drive assembly - vertical seal can provide preheating and heating operation to help the packer be better sealed. Therefore, the packaging items has better air tightness.

We adopt a reciprocating zigzag knife to perform perforated incisions. The zigzag incision of food bag makes the bag easier to tear.

| Max. Production Capacity | 80bag/min(According to different material size, and change) | |

| Max Width of Film | 630mm | |

| Max. Dia of Film | Ø350mm | |

| Shape of products | Round bar, rectangle and so on | |

| Packing | Length | 180~400mm |

| Width | 125~280mm | |

| Range | Height | 10~90mm |