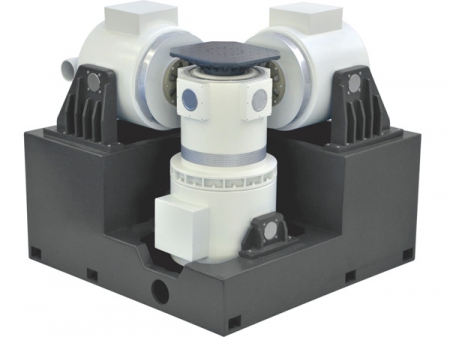

Vibration device of Continuous Casting Mold System

Vibration device plays a vital role in the whole casting process. Through vibration, it effectively avoids the initial frozen strand shell from being pulled apart caused by bonding with the mold system. It takes effect in demoulding. Our vibration device adopts sinusoidal vibration of short arm four-link. This device is made up of vibration rack, support, connecting rod, motor, reducer and other components. When operating, the motor drives the reducer with a eccentric device to drive the pushrod, thus achieving the sinusoidal vibration of the vibration rack. Its installation requires the position to be accurate and reliable. Sinusoidal vibration has strengths of gentle velocity change and no compact during the vibration.

During the operation, it necessary to choose reasonable amplitude and frequency. The experimental results show that high frequency and low amplitude ought to be selected to reduce the oscillation mark and crack on the billet surface. Before starting up, the air vent valve of the reducer should be loosened or pulled on to ensure the reducer and motor of good ventilation, draught and heat dissipation. Check the oil-level height of the lubrication and whether the rotation id flexible. Before running, the vibration device should operates for half hour in non-load condition. It can not run on-load until it is confirmed that there is no problem in no-load running. Keep out whether the temperature rise, sealing, noise and vibration are normal. Make sure the temperature rise is no higher than 45℃~60℃ after loading for two hours. After using for one month (200-300 hours) the first time, renew the lubricant and clean the internal oil contamination. Then change the lubricant every half year and note if the oil mass meets the requirements.