Mold Making Materials

Request a Quote

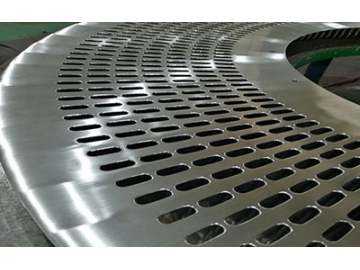

Raw materials for plastic molds is important to the mold manufacturing process, as it will influence the final service life of the finished molds- particularly those used to produce high end plastic products, or products that require a higher precision. We work with professional mold raw material suppliers, though customers can send us to their preferred supplier, and we will buy through them.

Commonly used plastic injection mold raw material:LKM, Baosteel, SKD, ASSAB, Goditz etc.

Commonly used steel:S136, H13, 718H, DIN1.2738, DIN1.2344, NAK80, DC53, LKM2316 etc.

High-quality plastic mold steel from German GroditzFeatures:- Uniform hardness

- Excellent polishing performance

- Good workability

- Pre-hardened plastic mold steel

- Nitriding permissible

- Adaptable to surface treatment (such as chrome plating)

- Resistant to corrosion

- Excellent polishing performance

- Resistant to abrasion

- Good workability

- High quenching stability

- Corrosion and rust resistant

High-quality steel raw materials can withstand corrosive injection molding materials, such as PVC (polyvinyl chloride) and acetate. These materials won't rust in humid environments. - Resistant to abrasion

High-quality steel materials can withstand abrasion from injection molding materials, such as thermoset injection molds, as well as withstand a relatively long work period, such as that used for molding of electronic components, dinnerware, containers and more. - Smooth surface

The steel material can also be used for the manufacturing of a variety of optical products, including cameras, sunglasses, chemical instruments, plastic products and more. The S136 steel also features an excellent polishing performance and corrosion resistance.

Related products

Send Message

Most Recent

More

Other Products

Videos