Slipform Construction

Construction Range

Slip form construction is a building method used to build tall structures and horizontal structures by pouring concrete into a continuously moving form in order to create seamless surfaces.

Cases and Construction Experience

Guoxin has undertaken slip form construction projects for numerous Chinese customers. In addition to traditional slip form construction, we also can offer special slip forming solutions.

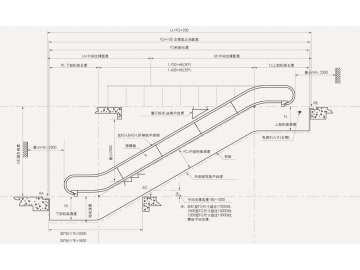

1. Hyperbolic cooling tower slip form construction

We used 1 hydraulic power pack and 12 YSQD-160-100 hydraulic slip form jacks for the construction of a hyperbolic cooling tower in Cangzhou power plant of Hebei province.

2. 210m chimney hydraulic slip form construction of Huaneng Dandong Power Plant

Advantages of Slip form Construction

1. The usage of the slip form construction process allows builders to eliminate the costs of scaffolding and other extra building equipment.

2. Slip form construction using slip form jacking equipment simplifies the formwork, reducing labor, material consumption, and reducing total construction time.

Main Characteristics of Slip form Construction

1. Traditional scaffolding technology

2. Precise dimensions

3. Smooth surface

4. Reduced requirement for wood

5. Integrated structure, without horizontal, and vertical construction joints

6. Easy to handle the concrete surface

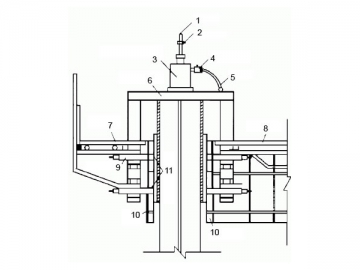

Structure and Principle

Slip Form Structure Diagram

1. Jack Rod

2. Jack Limit

3. GYD-60 Slip form Jack

4. Oil Distributor

5. Oil Pipe

6. Portal Type Lifting Frame

7. External Working Deck

8. Internal Working Deck

9. Adjusting Screw Rod

10. Slip Form

11. Slip Form Hook

Construction Scheme

Main Project Construction Method

Rebar Engineering

Rebar is produced on the construction site according to the drawing, and stacked in sequence, it can be lifted to operation platform by pulling bar. The rebar can be extended in slip forming process, the length of the single rebar is optional according to the diagram size but not more than 6m. The main rebar in the same section shall not exceed 25%, the thickness of circumferential rebar is 35mm, which is connected by binding, the overlapping length is 48×perimeter of the rebar, the joints between circumferential rebar should be staggered. Radius, radian and length of circumferential rebar can be customized according to the layout of actual working site.

Concrete Engineering

Concrete mixture proportion report is provided by quality inspection center, the construction will be started after local material testing is qualified. The water cement ratio is strictly controlled and mastered when mixes the concrete. The raw material should be weighed before using it, each wall with the height of 10m is used as a test block according to the concrete mixture proportion. The concrete formwork does not occur bleeding phenomenon, laying concrete should be symmetrical, and direction transformation should be simultaneous. Immersion vibrator is adopted, pouring direction should be vibrated in the same direction, pouring and tamping depth is about 300-400mm (that is the stroke of slip forming).

Cold joint treatment: It will have construction joint between the concrete which is pouring and tamping in the very day and the second day, so the joint should be deal with to avoid appearing honeycomb, cavity and pitted surface on it. The first step is to pour a mortar layer with the thickness of 5cm in the surface, and then pour and tamp the concrete.

Lining Engineering

The chimney adopts continuous slipping way, its lining and inside formwork are moving together. The material of lining is hanged by crane. Common brick of lining is built first and then mixed with cement perlite products. Bricklaying must be strictly in accordance with the design requirements and masonry standard. The vertical deviation is within ±80mm, the levelness is within 3mm, the saturation of mortar is more than 95%.

Chimney Jack

The thickness of the chimney jack is increased gradually, external formwork is tilted oppositely, so the upper hole of formwork will stop slipping at the place of tilting. When the concrete strength reaches 0.5-0.25Mpa, the external formwork will be released, the lower hole of formwork is lifted to the tilting place, and then the gradient of formwork will be adjusted, after all of them, the concrete will be poured, and this work will be cycled until the completion of the construction. Because of the gradient is large in the beginning, in order to reduce the slip height, the support rod should be fixed when the formwork is slipping.

Diameter Adjusting Process

The diameter adjusting device is also called the grading device, which is mounted on the radiation beam, and located on the outer side of the lifting frame, it is composed of square threaded rod (equips with square threaded screw and square threaded cap) with the diameter of 40-50mm, and the length of 40-50mm. The screw nut with a base is fixed on the radiation beam by a bolt. When the screw rod is twisted to the end which can be screwed back, and the screw base can be removed, at the same time, the screw rod is moved inwards along the radiation beam.

Concrete Curing

The concrete is cured by curing liquid, concrete surface should be coated by curing liquid after concrete formwork is out. Before pouring concrete, the original concrete surface should be cleaned and then poured cement mortar with the thickness of 30-50mm, after that the concrete should be poured two layers with the thickness of 60mm respectively. The concrete should be vibrated in each pouring thickness that reaches 300mm, when pouring to the 1/2 height of formwork, the formwork should be lifted 1-2 stroke. The first layer concrete strength reaches 0.05~0.25Mpa, the pouring direction should be changed constantly, that is helpful to reduce friction drag and platform torsion. Each time of pouring should leave a circumferential rebar outside of the concrete, in order to ensure the distance of binding circumferential rebar, the exposed reinforcing bar or flaw have to repaired immediately by fine stone concrete or cement mortar after formwork is removed.

Normal Sliding

When normally slide, there are two big holes (in chimney) and the climbing pole climb along the jack, but as it will weaken the carrying capacity of climbing pole, so need to do the reinforcement, therefore, when slide through the two holes, the pole need to be reinforced to increase the compression capability, strength and stability. The normal sliding is day and night 3m, and every time lifting (300mm) must be strictly inspected, the center deviation should be controled in the range of 0.5%

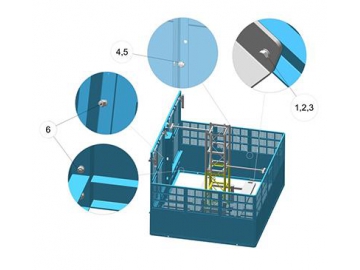

Hydraulic Lifting Method of Upside-down Construction for Large Storage Tank

Characteristic

1.1 Upside-down Method Construction, height operation changed to ground operation.

1.2 Jacking way changed to lifting way.

1.3 Mechanical system changed to hydraulic mechanism, large output, small equipment

1.4 Individual control changed to central control

1.5 Moving parts with lubrication changed to without lubrication

1.6 Continuous lifting changed to stepping lifting, lifting height (theoretically) unlimited.

1.7 Rigid force changed to spherical self pull bending moment unloading mechanism

1.8 The mechanical efficiency, volume weight, output, security and others are improved compared with the original construction method.

Process Principles

2.1 Principles of Upside-down Method

The cylindrical metal tank body consists of three parts: Tank bottom, wall panels, tank top. The height of tank body is formed by each section of wall panel. The steps of upright method are: Tank bottom - Each section of wall panel – Tank top. With higher and higher tank body, must work at heights. The steps of upside down method are: Tank body – Tank top – Upper wall panel – Lifting – Lower wall panel – Lifting – Each section of wall panel. The construction of main body is all ground operation, not only safe, high efficiency, but also save the cranes, scaffolding and other expenses. The tank top and the lifting upper wall panel must use expansion ring, according to the tank inner diameter, the expansion ring is divided as several segments, every two segments should use jack to fix them in the tank wall, and weld the rib plate to ensure the force transfer of expansion ring tank. The lifting mechanism lift the expansion ring, then the tank top and upper wall panel will be lifted. After welding the lower wall panel, install the expansion ring to the lower wall panel, repeat work, until complete the construction of all the wall panel.